I-foil yeCopper efakwe kwiTin

Intshayelelo yeMveliso

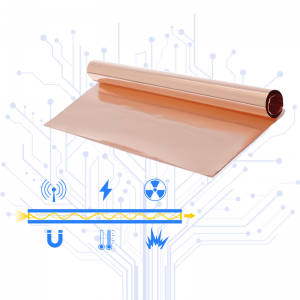

Iimveliso zobhedu ezivezwa emoyeni zinokuba yingozi kakhuluioksijinikunye nokwakheka kwe-basic copper carbonate, enokumelana okuphezulu, umbane ongasebenzi kakuhle kunye nokulahleka kokudluliselwa kwamandla aphezulu; emva kokufakwa kwe-tin plating, iimveliso ze-copper zenza iifilimu ze-tin dioxide emoyeni ngenxa yeempawu ze-tin metal ngokwayo ukuthintela i-oxidation engaphezulu.

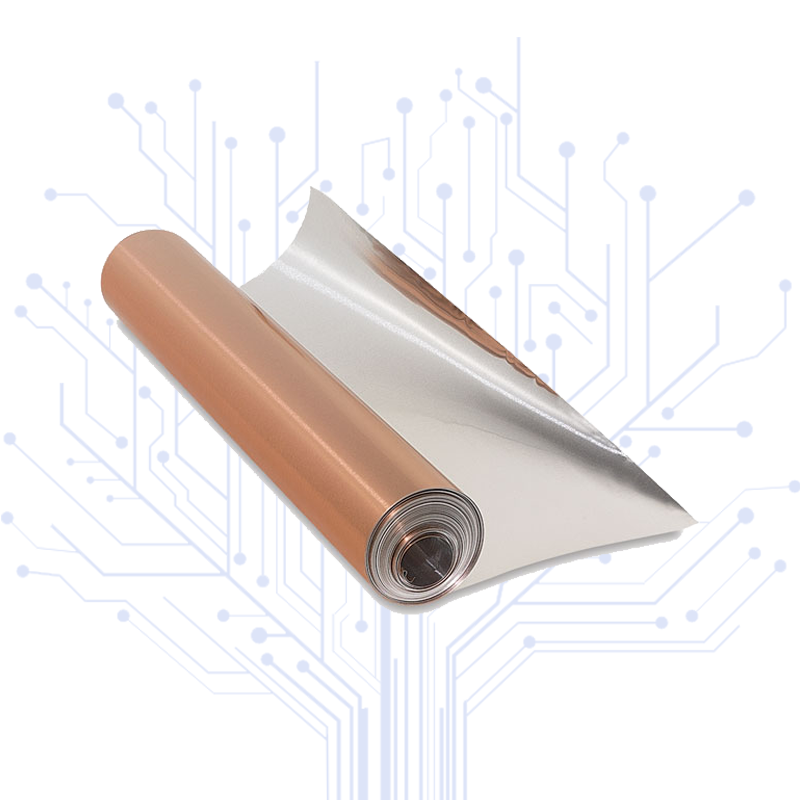

Izinto ezisisiseko

●Ifoyile yeCopper eRholiweyo echanekileyo kakhulu, iCu(JIS: C1100/ASTM: C11000) engaphezulu kwe-99.96%

Uluhlu loButyebi beZinto eziSeko

●0.035mm~0.15mm (0.0013 ~0.0059intshi)

Uluhlu lobubanzi bezinto ezisisiseko

●≤300mm (≤11.8 intshi)

Ubushushu bezinto ezisisiseko

●Ngokweemfuno zabathengi

Isicelo

●Izixhobo zombane kunye nemizi-mveliso ye-elektroniki, imboni yoluntu (ezifana: nokupakisha iziselo kunye nezixhobo zokunxibelelana nokutya);

Iiparameters zokuSebenza

| Izinto | Isingxobo seTin esiWeldayo | Isingxobo seTin esingawelisiyo |

| Uluhlu lobubanzi | ≤600mm (≤23.62inches) | |

| Uluhlu Lobukhulu | 0.012~0.15mm (0.00047inches~0.0059inches) | |

| Ubukhulu beleyara yetin | ≥0.3µm | ≥0.2µm |

| Umxholo weTin kwiLayer yeTin | 65~92% (Ingalungisa umxholo wetin ngokwenkqubo yokuwelda yabathengi) | I-tin ecocekileyo eyi-100% |

| Ukumelana nomphezulu we-Tin Layer(Ω) | 0.3~0.5 | 0.1~0.15 |

| Ukunamathela | 5B | |

| Tensile strength | Ukuncitshiswa kokusebenza kwezinto ezisisiseko emva kokufakelwa ≤10% | |

| Ukwandiswa | Ukuncitshiswa kokusebenza kwezinto ezisisiseko emva kokufakelwa kweplati ≤6% | |

![[VLP] I-ED Copper Foil esezantsi kakhulu](https://cdn.globalso.com/civen-inc/VLP-Very-Low-Profile-ED-Copper-Foil-300x300.png)