Iimveliso

-

Ifoyile yeCopper elwa neentsholongwane

I-Copper yeyona ntsimbi imele kakhulu enefuthe lokubulala iintsholongwane. Uvavanyo lwenzululwazi lubonise ukuba i-copper inako ukuthintela ukukhula kweebhaktheriya ezahlukeneyo eziphazamisa impilo, iintsholongwane kunye neentsholongwane ezincinci.

-

Ifoyile yeCopper elwa nokugqwala

Ngophuhliso oluqhubekayo lwetekhnoloji yanamhlanje, ukusetyenziswa kwefoyile yobhedu kuye kwanda ngakumbi nangakumbi. Namhlanje sibona ifoyile yobhedu kungekuphela nje kumashishini athile emveli afana neebhodi zesekethe, iibhetri, izixhobo ze-elektroniki, kodwa nakwamanye amashishini akwizinga eliphezulu, njengamandla amatsha, iitships ezidibeneyo, unxibelelwano oluphezulu, i-aerospace kunye namanye amacandelo.

-

Iteyiphu yeFoyile yeCopper enamathelayo

Iteyiphu yefoyile yobhedu eqhubayo enye ibhekisa kwelinye icala elinomphezulu onamathelayo ongaqhubiyo, kwaye lingenanto kwelinye icala, ukuze likwazi ukuqhuba umbane; ngoko ke libizwa ngokuba yifoyile yobhedu eqhubayo enye icala.

-

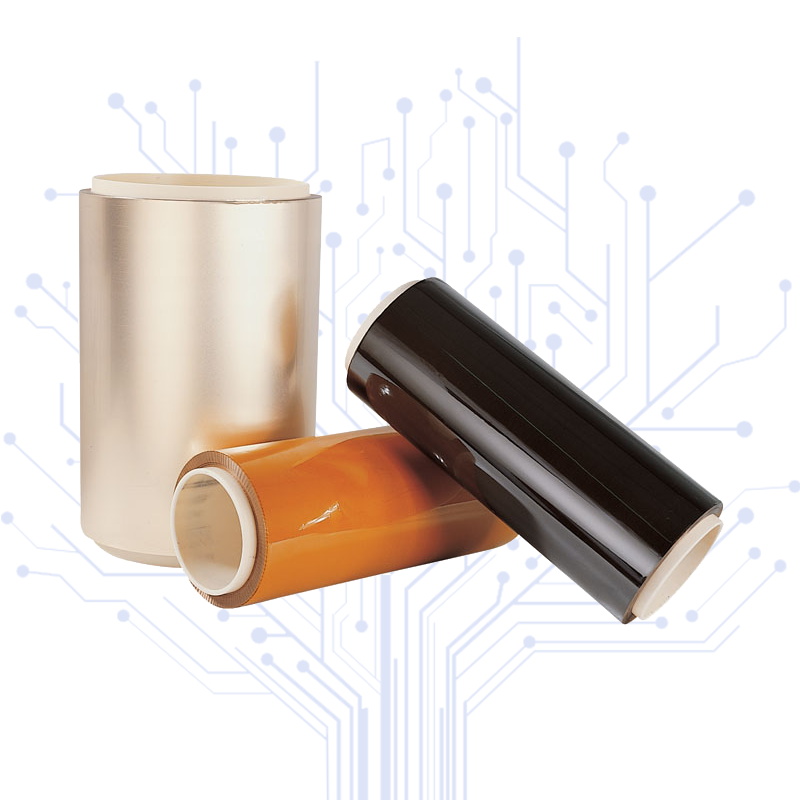

I-3L Flexible Copper Clad Laminate

Ukongeza kwiingenelo zokuba mncinci, ulula kwaye uguquguqukayo, i-FCCL enefilimu esekelwe kwi-polyimide ikwanazo neempawu zombane ezibalaseleyo, iimpawu zobushushu, kunye neempawu zokumelana nobushushu. I-dielectric constant yayo ephantsi (DK) yenza imiqondiso yombane idluliseleke ngokukhawuleza.

-

I-Laminate yeCopper eguquguqukayo ye-2L

Ukongeza kwiingenelo zokuba mncinci, ulula kwaye uguquguqukayo, i-FCCL enefilimu esekelwe kwi-polyimide ikwanazo neempawu zombane ezibalaseleyo, iimpawu zobushushu, kunye neempawu zokumelana nobushushu. I-dielectric constant yayo ephantsi (DK) yenza imiqondiso yombane idluliseleke ngokukhawuleza.

-

I-Electrolytic Pure NickelFoil

I-electrolytic nickel foil eyenziwe yiIsinyithi Esiyilwe Ngomoyaisekelwe kwi1#i-nickel ye-electrolytic njengezinto eziluhlaza, kusetyenziswa indlela ye-electrolytic yokucubungula nzulu ukukhupha i-foil.

-

Umcu wobhedu

Umcu wobhedu wenziwe ngobhedu olusebenzisa i-electrolytic, ngokucutshungulwa nge-ingot, ukuqengqeleka okushushu, ukuqengqeleka okubandayo, unyango lobushushu, ukucoca umphezulu, ukusika, ukugqiba, uze emva koko upakishwe.

-

Umcu wobhedu

Iphepha leBrass elisekwe kwi-electrolytic copper, zinc kunye nezinto ezilandelelanayo njengezinto zalo eziluhlaza, ngokusebenzisa i-ingot, i-hot rolling, i-cold rolling, unyango lobushushu, ukucoca umphezulu, ukusika, ukugqiba, uze emva koko upakishe.

-

Umtya weCopper kwiSakhelo seNkokeli

Izinto ezisetyenziswa kwisakhelo se-lead zihlala zenziwe nge-alloy yobhedu, i-Iron kunye ne-phosphorus, okanye i-copper, i-nickel kunye ne-silicon, ezine-alloy eqhelekileyo ye-C192(KFC), i-C194 kunye ne-C7025. Ezi alloys zinamandla aphezulu kunye nokusebenza kakuhle.

-

Ukuhombisa iCopper Strip

I-Copper ibisoloko isetyenziswa njengezinto zokuhombisa ixesha elide. Ngenxa yokuba le nto ithambile kwaye inokumelana nokugqwala okuhle.

-

Iphepha leCopper

Iphepha leCopper lenziwe nge-electrolytic copper, ngokusebenzisa i-ingot, i-hot rolling, i-cold rolling, i-heat treatment, i-supplement cold treatment, i-surface cleaning, i-cutting, i-finishing, ize ipakishwe.

-

Iphepha leBrass

Iphepha leBrass elisekwe kwi-electrolytic copper, zinc kunye nezinto ezilandelelanayo njengezinto zalo eziluhlaza, ngokusebenzisa i-ingot, i-hot rolling, i-cold rolling, unyango lobushushu, ukucoca umphezulu, ukusika, ukugqiba, kunye nokupakisha. Ukusebenza kweenkqubo zezinto, i-plasticity, iipropati zoomatshini, ukumelana nokugqwala, ukusebenza kunye ne-tin elungileyo.