Ishishini lemathiriyeli yePCB lichithe ixesha elininzi lokuphuhlisa izixhobo ezibonelela ngelahleko yophawu olusezantsi kunokwenzeka. Kwisantya esiphezulu kunye noyilo oluphezulu lwefrikhwensi, ilahleko iya kunciphisa umgama wokusasazwa komqondiso kunye nemiqondiso egqwethekileyo, kwaye iya kudala ukutenxa kwe-impedance okunokubonwa kwimilinganiselo ye-TDR. Njengoko siyila nayiphi na ibhodi yesekethe eprintiweyo kwaye siphuhlisa iisekethe ezisebenza kumaza aphezulu, kunokuhenda ukukhetha ubhedu olugudileyo kulo lonke uyilo olwenzayo.

Ngelixa kuyinyani ukuba uburhabaxa bobhedu budala ukutenxa okongeziweyo kunye nelahleko, ingaba ifoyile yakho yobhedu ifuna ukuba lula kangakanani? Ngaba zikhona iindlela ezilula onokuzisebenzisa ukoyisa ilahleko ngaphandle kokukhetha ubhedu olugudileyo kuyilo ngalunye? Siza kujonga la manqaku kweli nqaku, kwakunye nento onokuyijonga xa uqala ukuthengela izixhobo zokupakisha zePCB.

Iintlobo zeI-PCB ye-Copper Foil

Ngokuqhelekileyo xa sithetha ngobhedu kwizinto ze-PCB, asithethi ngohlobo oluthile lobhedu, sithetha kuphela ngoburhabaxa balo. Iindlela ezahlukeneyo zokubeka ubhedu zivelisa iifilimu ezinamaxabiso ahlukeneyo okurhabaxa, anokwahlulwa ngokucacileyo kumfanekiso we-electron microscope (SEM) wokuskena. Ukuba uza kusebenza kumaza aphezulu (aqhele ukuba yi-5GHz WiFi okanye ngaphezulu) okanye ngesantya esiphezulu, ngoko ke qwalasela uhlobo lobhedu oluchazwe kwidatha yakho yedatha.

Kwakhona, qiniseka ukuba uyayiqonda intsingiselo yamaxabiso kaDkt kwidatha yedatha. Bukela le ngxoxo yepodcast kunye noJohn Coonrod ovela kuRogers ukufunda ngakumbi malunga nokucaciswa kukaDkt. Unaloo nto engqondweni, makhe sijonge ezinye iintlobo ezahlukeneyo PCB ifoyile yobhedu.

Electrodeposited

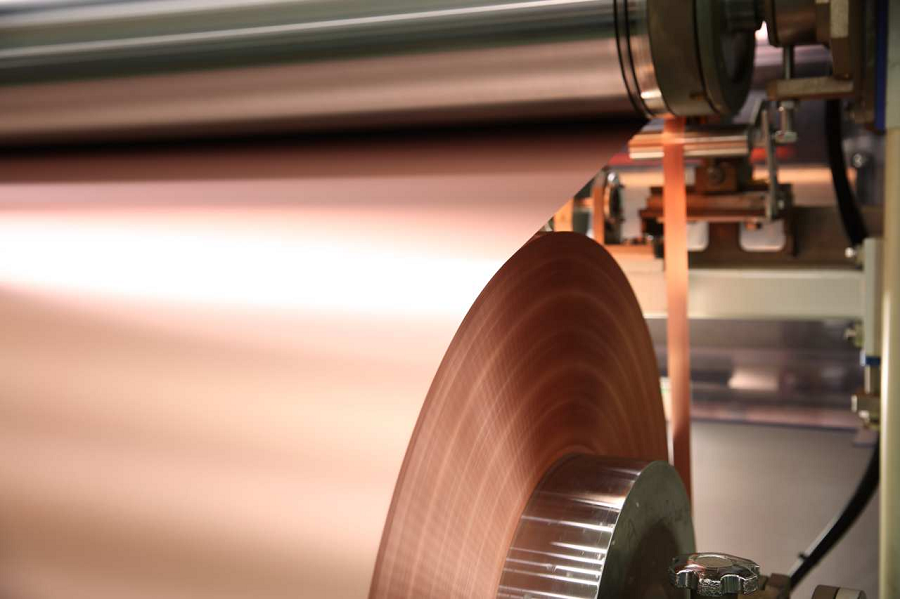

Kule nkqubo, i-drum iphonswa ngesisombululo se-electrolytic, kwaye i-electrodeposition reaction isetyenziselwa "ukukhulisa" i-foil yobhedu kwi-drum. Njengoko igubu lijikeleza, ifilimu yobhedu ephumayo ibotshelelwa kancinane kwirola, inika icwecwe lobhedu eliqhubekayo elinokuthi kamva liqengqeleke kwi-laminate. Icala legubu lobhedu liya kuhambelana noburhabaxa begubu, ngelixa icala eliveziweyo liya kuba rhabaxa kakhulu.

Electrodeposited PCB ifoyile yobhedu

Electrodeposited copper production.

Ukuze isetyenziswe kwinkqubo yokwenziwa kwe-PCB eqhelekileyo, icala elirhabaxa lobhedu liya kuqala libotshwe kwi-glass-resin dielectric. Ubhedu olushiyekileyo (icala legubu) luya kufuna ukwenziwa rhabaxa ngabom ngokwemichiza (umz., ngokukrolwa kweplasma) phambi kokuba isetyenziswe kwinkqubo yonyibiliko yentsimbi yobhedu. Oku kuya kuqinisekisa ukuba inokudityaniswa kumaleko olandelayo kugcino lwePCB.

ICopper ene-Electrodeposited phezu komhlaba

Andazi elona gama lifanelekileyo elibandakanya zonke iintlobo ezahlukeneyo zokunyangwa komphezuluiifoyile zobhedu, ngaloo ndlela isihloko singasentla. Ezi zixhobo zobhedu zaziwa kakhulu njengeefoyile eziphathwayo, nangona ezinye iinguqulelo ezimbini zikhoyo (jonga ngezantsi).

Iifoyile eziphathwayo ezibuyiselwe umva zisebenzisa unyango olungaphezulu olusetyenziswa kwicala eligudileyo (icala legubu) lephepha lobhedu eline-electrodeposited. Umaleko wonyango yityabeka nje ebhityileyo erhabaxa ngabom ubhedu, ngoko iya kuba nokuncamathela okukhulu kwisixhobo se-dielectric. Olu nyango lukwasebenza njengesithintelo se-oxidation esithintela ukubola. Xa olu bhedu lusetyenziselwa ukwenza iipaneli ze-laminate, icala eliphathwayo liboshwe kwi-dielectric, kwaye icala eliseleyo elibi lihlala libonakaliswe. Icala eliveziweyo aliyi kufuna nayiphi na i-roughening eyongezelelweyo phambi kokukrolwa; iya kuba sele inamandla aneleyo okubophelela kumaleko olandelayo kugcino lwePCB.

Izahluko ezintathu kwi-foil yobhedu enyangweni ibandakanya:

Ukuphakama kweqondo lokushisa eliphezulu (HTE) icwecwe lobhedu: Le yifoyile yobhedu ene-electrodeposited ehambelana ne-IPC-4562 yeBanga lesi-3. Ubuso obuvezwayo bukwaphathwa ngesithintelo se-oxidation ukuthintela ukubola ngexesha lokugcinwa.

I-foil ephindwe kabini: Kule foyile yobhedu, unyango lusetyenziswa kumacala omabini efilimu. Le nto ngamanye amaxesha ibizwa ngokuba yi-drum-side foil ephathwayo.

Ubhedu oluxhathisayo: Oku aluqhelekanga ukuhlelwa njengobhedu olucociwe phezulu. Le foil yobhedu isebenzisa intsimbi ehonjiswe phezu kwecala le-matte lobhedu, elithi ke libe rhabaxa ukuya kwinqanaba elifunekayo.

Ukusetyenziswa kwonyango lwangaphezulu kwezi zixhobo zobhedu zichanekile: i-foil iqengqeleka ngeebhafu ezongezelelweyo ze-electrolyte ezisebenzisa i-plating yobhedu yesibini, ilandelwa ngumqobo wembewu yesithintelo, kwaye ekugqibeleni i-anti-tarnish layer.

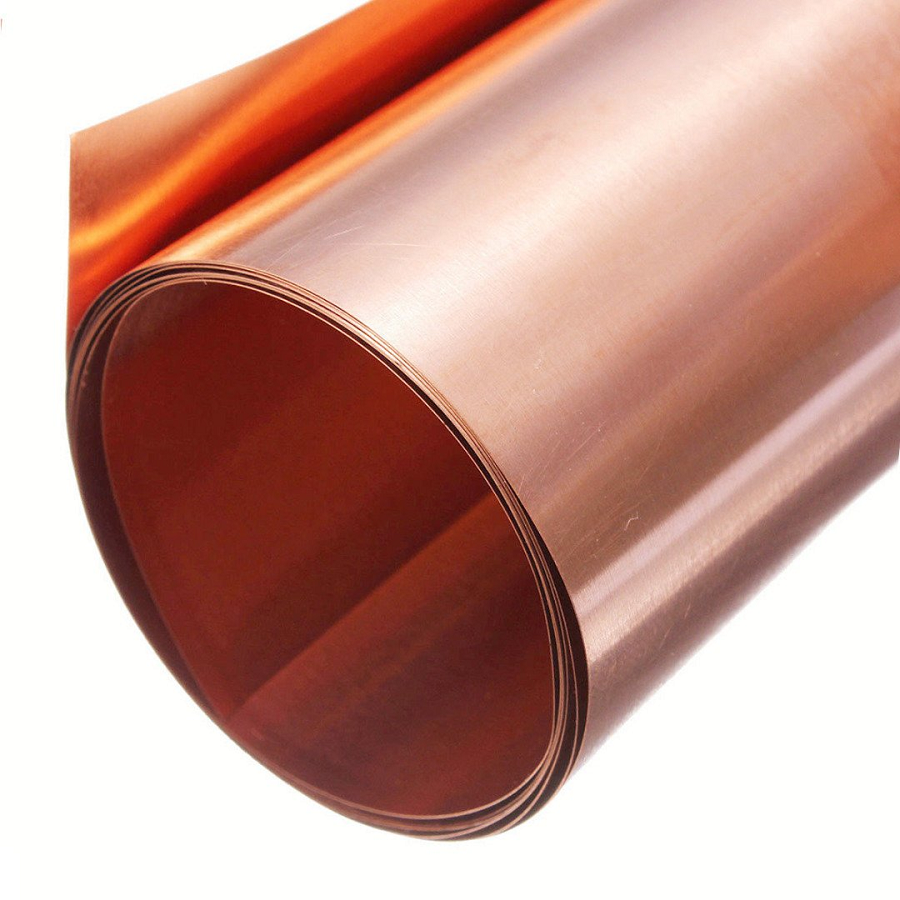

PCB ifoyile yobhedu

Iinkqubo zokunyanga ubuso kwiifoyile zobhedu. [Umthombo: Pytel, uSteven G., et al. "Uhlalutyo lwezonyango zobhedu kunye nemiphumo ekusasazeni umqondiso." Kwi-2008 i-58 ye-Electronic Components kunye neNkomfa yeTekhnoloji, iphepha 1144-1149. IEEE, 2008.]

Ngezi nkqubo, unezinto eziphathekayo ezinokusetyenziswa ngokulula kwinkqubo yokwenziwa kwebhodi esemgangathweni kunye nokulungiswa okuncinci okongeziweyo.

Ubhedu Oluqengqelelweyo

Iifoyile zobhedu ezigoqiweyo ziya kudlula umqulu wefoyile yethusi ngokusebenzisa i-roller, eya kubanda i-copper-roll sheet ukuya kubukhulu obufunwayo. Ubunzima bephepha le-foil elibangelwayo liya kuhluka ngokuxhomekeke kwiiparamitha ezijikelezayo (isantya, uxinzelelo, njl.).

Iphepha eliphumelayo linokuba lula kakhulu, kwaye imigqaliselo ibonakala kumphezulu wephepha le-copper edibeneyo. Imifanekiso engezantsi ibonisa uthelekiso phakathi kwe-electrodeposited copper foil kunye ne-rolled-annealed foil.

PCB ifoyile yobhedu uthelekiso

Ukuthelekiswa kwe-electrodeposited vs.

ICopper eneProfayile ephantsi

Oku akunyanzelekanga ukuba luhlobo lwefoyile yobhedu ongayenza ngenye inkqubo. Ubhedu olusezantsi luyi-electrodeposited copper ephathwayo kwaye iguqulwe ngenkqubo ye-micro-roughening ukubonelela uburhabaxa obusezantsi kakhulu obunoburhabaxa obaneleyo bokuncamathela kwi-substrate. Iinkqubo zokwenza ezi foil zobhedu zikholisa ukuba zezabantu. Ezi foil zihlala zihlelwa njenge-ultra-low profile (ULP), iprofayile ephantsi kakhulu (VLP), kunye neprofayile esezantsi nje (LP, malunga ne-1 micron eyi-avareji yoburhabaxa).

Amanqaku anxulumeneyo:

Kutheni iFoil yobhedu isetyenziswa kwiPCB Manufacturing?

Ifoyile yobhedu esetyenziswa kwiBhodi yeSekethe eprintiweyo

Ixesha lokuposa: Jun-16-2022