Ishishini lezinto ze-PCB lichithe ixesha elininzi liphuhlisa izinto ezibonelela ngokulahleka kwesignali okuncinci kangangoko. Kwimizobo yesantya esiphezulu kunye ne-frequency ephezulu, ilahleko ziya kunciphisa umgama wokusasazeka kwesignali kwaye zijike imiqondiso, kwaye ziya kudala ukuphambuka kwe-impedance okunokubonwa kwimilinganiselo ye-TDR. Njengoko siyila nayiphi na ibhodi yesekethe eprintiweyo kwaye siphuhlisa iisekethe ezisebenza kwii-frequency eziphezulu, kunokuba nzima ukukhetha ubhedu oluthambileyo kuzo zonke iidizayini ozenzayo.

Nangona kuyinyani ukuba uburhabaxa bekopolo kudala ukuphambuka kunye nokulahleka kwe-impedance eyongezelelweyo, kufuneka i-copper foil yakho igude kangakanani ngokwenene? Ngaba kukho iindlela ezilula onokuzisebenzisa ukoyisa ilahleko ngaphandle kokukhetha i-copper egudileyo kakhulu kuyo yonke idizayini? Siza kujonga la manqaku kweli nqaku, kunye noko unokukujonga ukuba uqala ukuthenga izinto ze-PCB stackup.

Iintlobo zeIfoyile yeCopper yePCB

Ngokwesiqhelo xa sithetha ngobhedu kwizinto zePCB, asithethi ngohlobo oluthile lobhedu, sithetha kuphela ngoburhabaxa balo. Iindlela ezahlukeneyo zokubeka ubhedu zivelisa iifilimu ezinexabiso elihlukeneyo loburhabaxa, ezinokwahlulwa ngokucacileyo kumfanekiso we-scanning electron microscope (SEM). Ukuba uza kusebenza kwiifrikhwensi eziphezulu (ngesiqhelo i-5 GHz WiFi okanye ngaphezulu) okanye ngesantya esiphezulu, ke qwalasela uhlobo lobhedu oluchazwe kwiphepha ledatha lezinto zakho.

Kwakhona, qiniseka ukuba uyayiqonda intsingiselo yamaxabiso e-Dk kwiphepha ledatha. Bukela le ngxoxo ye-podcast noJohn Coonrod waseRogers ukuze ufunde okungakumbi malunga neenkcukacha ze-Dk. Sicinga ngaloo nto, makhe sijonge ezinye zeentlobo ezahlukeneyo ze-PCB copper foil.

Ifakwe kwi-electrode

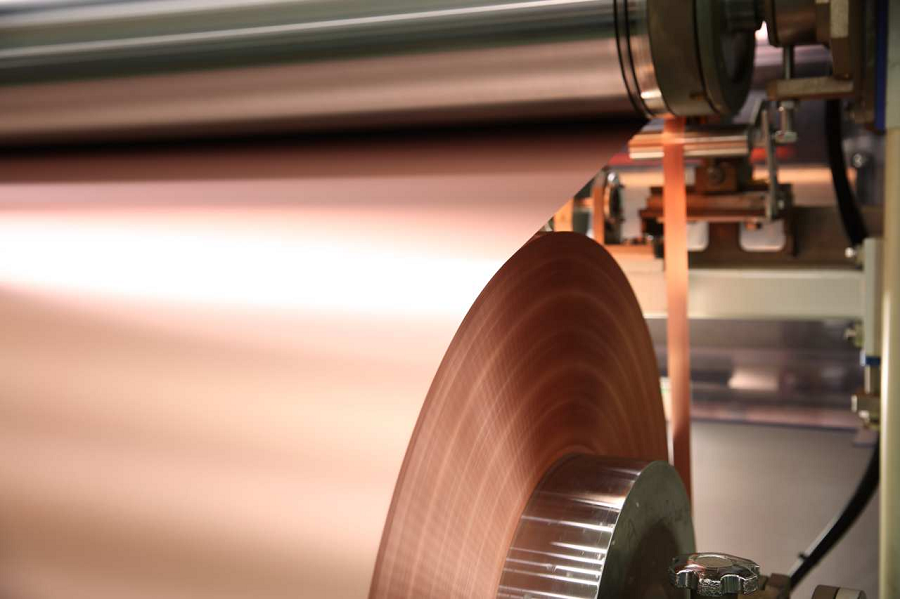

Kule nkqubo, idrama ijikeleziswa ngesisombululo se-electrolytic, kwaye i-electrodeposition reaction isetyenziselwa "ukukhulisa" i-copper foil kwidrama. Njengoko idrama ijikeleza, ifilimu yobhedu ephumayo igqunywa kancinci kwi-roller, inika iphepha lobhedu eliqhubekayo elinokuqengqeleka kamva kwi-laminate. Icala ledrama lobhedu liya kufana noburhabaxa bedrama, ngelixa icala elibonakalayo liya kuba rhabaxa ngakumbi.

Ifoyile yobhedu yePCB efakwe kwi-electrode

Imveliso yobhedu olufakwe kwi-electrode.

Ukuze isetyenziswe kwinkqubo eqhelekileyo yokwenziwa kwe-PCB, icala elirhabaxa lethusi liya kuqala libotshelelwe kwi-dielectric yeglasi-resin. Ithusi eliseleyo eliveziweyo (icala ledrama) kuya kufuneka licocwe ngabom ngokwekhemikhali (umz., nge-plasma etching) ngaphambi kokuba lisetyenziswe kwinkqubo eqhelekileyo ye-copper clad lamination. Oku kuya kuqinisekisa ukuba libotshelelwe kumaleko olandelayo kwi-PCB stackup.

Ubhedu olufakwe kwi-electrode oluphathwe ngaphezulu

Andazi igama elingcono eliquka zonke iintlobo ezahlukeneyo zokulungiswa komphezuluiifoyile zobhedu, yiyo loo nto isihloko esingentla. Ezi zinto zobhedu zaziwa kakhulu njengeefoyile ezilungisiweyo ngasemva, nangona kukho ezinye iintlobo ezimbini ezikhoyo (jonga ngezantsi).

Iifoyile ezilungisiweyo ngasemva zisebenzisa unyango lomphezulu olusetyenziswa kwicala eligudileyo (icala leedrum) lephepha lethusi elifakwe i-electrodeposition. Umaleko wonyango luphawu oluncinci oluqoba ubhedu ngabom, ngoko ke luya kuba nokunamathela okukhulu kwizinto ezisebenzisa i-dielectric. Olu nyango lukwasebenza njengomqobo we-oxidation othintela ukugqwala. Xa olu bhedu lusetyenziselwa ukwenza iiphaneli ze-laminate, icala elilungisiweyo libotshelelwa kwi-dielectric, kwaye icala eliseleyo elirhabaxa lihlala livelile. Icala elivulekileyo aliyi kufuna naluphi na urhabaxa olongezelelweyo ngaphambi kokugqwala; liya kuba namandla aneleyo okubopha kumaleko olandelayo kwi-PCB stackup.

Iintlobo ezintathu zefoyile yobhedu ephathwe ngasemva ziquka:

Ifoyile yobhedu ende kakhulu (HTE): Le yifoyile yobhedu ebekwe nge-electrodeposition ehambelana nemigaqo ye-IPC-4562 yeBanga lesi-3. Ubuso obuveziweyo buphathwa ngesithintelo se-oxidation ukuthintela ukugqwala ngexesha lokugcina.

Ifoyile ephathwa kabini: Kule foyile yobhedu, unyango lusetyenziswa kumacala omabini efilimu. Le nto ngamanye amaxesha ibizwa ngokuba yifoyile ephathwa ngedrum-side.

I-copper ekhuselayo: Le ayiqhelekanga ukubekwa njenge-copper ecociweyo phezu komhlaba. Le foil ye-copper isebenzisa i-metallic coating phezu kwecala eli-matte le-copper, ethi emva koko i-roughed ifikelele kwinqanaba elifunekayo.

Ukusetyenziswa konyango lomphezulu kwezi zinto zobhedu kulula: ifoyile iqengqwa kwiibhafu ezongezelelweyo ze-electrolyte ezifaka ipleyiti yesibini yobhedu, ilandelwe yi-barrier seed layer, kwaye ekugqibeleni yi-anti-darnish film layer.

Ifoyile yobhedu yePCB

Iinkqubo zokunyanga umphezulu weefoyile zobhedu. [Umthombo: UPytel, Steven G., et al. "Uhlalutyo lonyango lobhedu kunye nemiphumo yokusasazeka kwesignali." KwiNkomfa yama-58 ye-Electronic Components and Technology ka-2008, iphe. 1144-1149. IEEE, 2008.]

Ngezi nkqubo, unezixhobo ezinokusetyenziswa ngokulula kwinkqubo yokwenziwa kwebhodi eqhelekileyo kunye nokulungiswa okuncinci okongeziweyo.

Ubhedu oluqengqelekayo

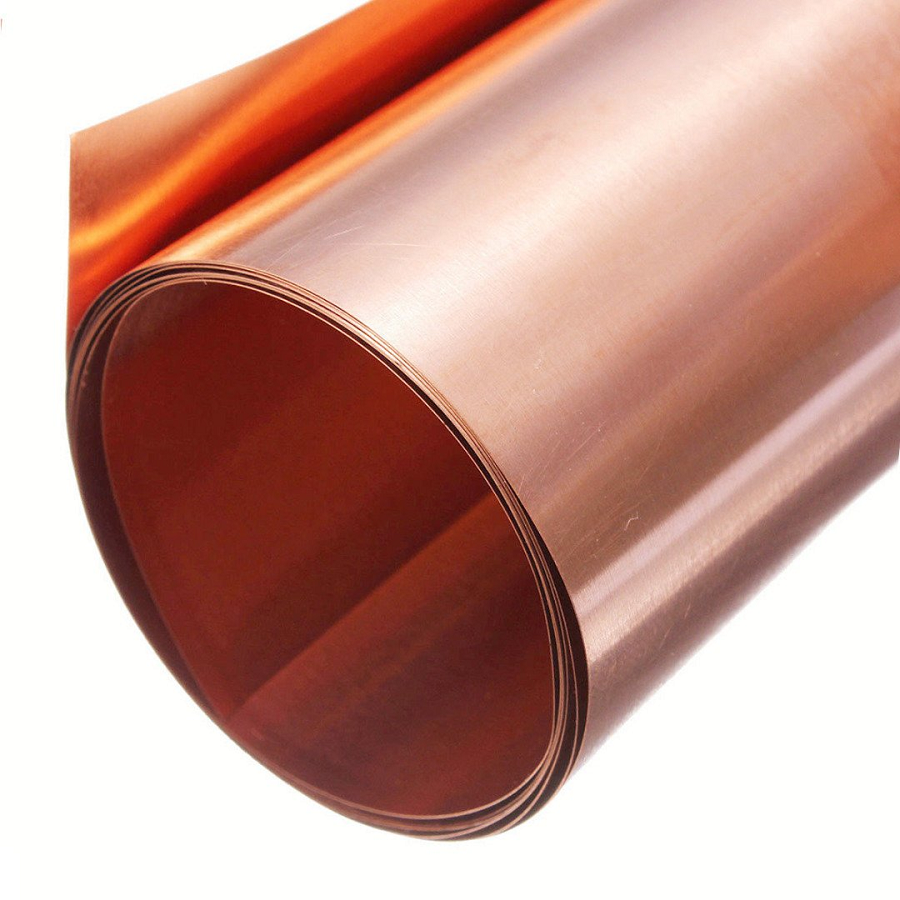

Iifoyile zobhedu eziqengqelweyo ziya kudlula umqulu wefoyile yobhedu kwiiroli ezimbini, eziya kuqengqeleka ngokubandayo ishiti yobhedu ukuya kubukhulu obufunekayo. Uburhabaxa beshiti yefoyile ephumayo buya kwahluka ngokuxhomekeke kwiiparameter zokuqengqeleka (isantya, uxinzelelo, njl.njl.).

Iphepha eliphumayo linokuba bushelelezi kakhulu, kwaye imiqolo ibonakala kumphezulu wephepha lobhedu eligoqiweyo. Imifanekiso engezantsi ibonisa uthelekiso phakathi kwefoyile yobhedu efakwe i-electrodeposition kunye nefoyile egoqiweyo.

Uthelekiso lwefoyile yobhedu yePCB

Ukuthelekiswa kweefoyile ezifakwe i-electrodeposition kunye neefoyile eziqengqelekayo.

Ithusi Eliphantsi

Olu ayilohlobo lwefoyile yobhedu onokuthi ulwenze ngenye indlela. I-low-profile copper yi-electrodepositioned copper ephathwayo kwaye iguqulwe nge-micro-roughening process ukuze ibonelele nge-low average roughness kunye ne-roughening eyaneleyo yokunamathela kwi-substrate. Iinkqubo zokwenza ezi foyile zobhedu zihlala ziyimfihlo. Ezi foyile zihlala zihlelwa njenge-ultra-low profile (ULP), very low profile (VLP), kunye ne-low-profile nje (LP, malunga ne-1 micron average roughness).

Amanqaku anxulumeneyo:

Kutheni iCopper Foil isetyenziswa kwiPCB Manufacturing?

I-Copper Foil esetyenziswa kwiBhodi yeSekethe eprintiweyo

Ixesha lokuthumela: Juni-16-2022