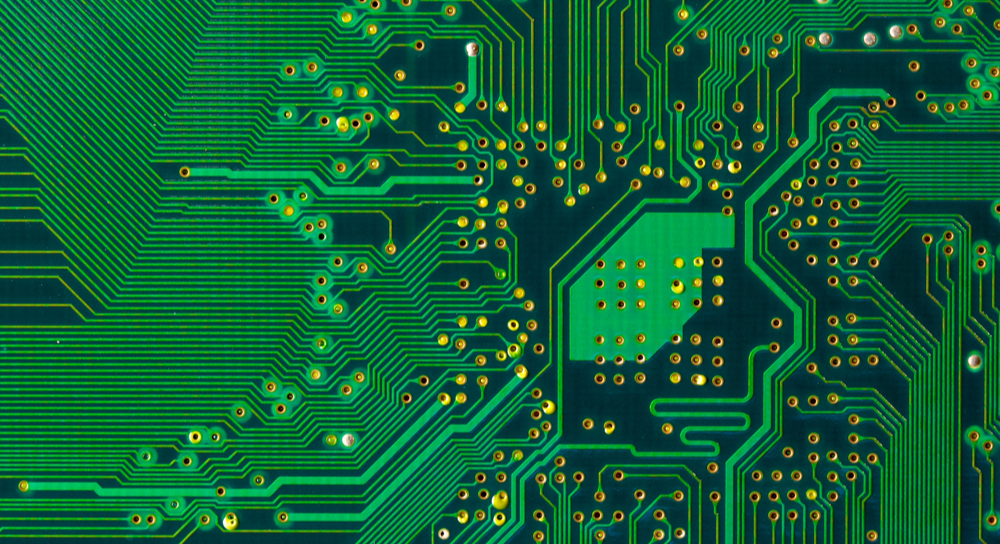

Iibhodi zesekethe eziprintiweyo zizinto eziyimfuneko kwizixhobo ezininzi zombane. Ii-PCB zanamhlanje zineeleya ezahlukeneyo: i-substrate, ii-traces, i-solder mask, kunye ne-silkscreen. Enye yezona zinto zibalulekileyo kwi-PCB yi-copper, kwaye kukho izizathu ezahlukeneyo zokuba kusetyenziswe i-copper endaweni yezinye ii-alloys ezifana ne-aluminium okanye i-tin.

Zenziwe Ngantoni iiPCB?

Ngokutsho kwenkampani ye-PCB assembly, ii-PCB zenziwe ngento ebizwa ngokuba yi-substrate, eyenziwe nge-fiberglass eqiniswe nge-epoxy resin. Ngaphezulu kwe-substrate kukho umaleko we-copper foil onokubotshelelwa kumacala omabini okanye kwelinye kuphela. Nje ukuba i-substrate yenziwe, abavelisi babeka izinto kuyo. Basebenzisa i-solder mask kunye ne-silkscreen kunye nee-resistor, ii-capacitors, ii-transistors, ii-diodes, ii-circuit chips, kunye nezinye izinto ezikhethekileyo.

Kutheni iCopper Foil isetyenziswa kwiPCBs?

Abavelisi be-PCB basebenzisa ubhedu kuba lunombane ophezulu kunye nobushushu. Njengoko umbane uhamba kunye ne-PCB, ubhedu lugcina ubushushu bungonakalisi kwaye bucinezele yonke i-PCB. Ngezinye ii-alloys - ezifana ne-aluminium okanye i-tin - i-PCB inokufudumala ngokulinganayo kwaye ingasebenzi kakuhle.

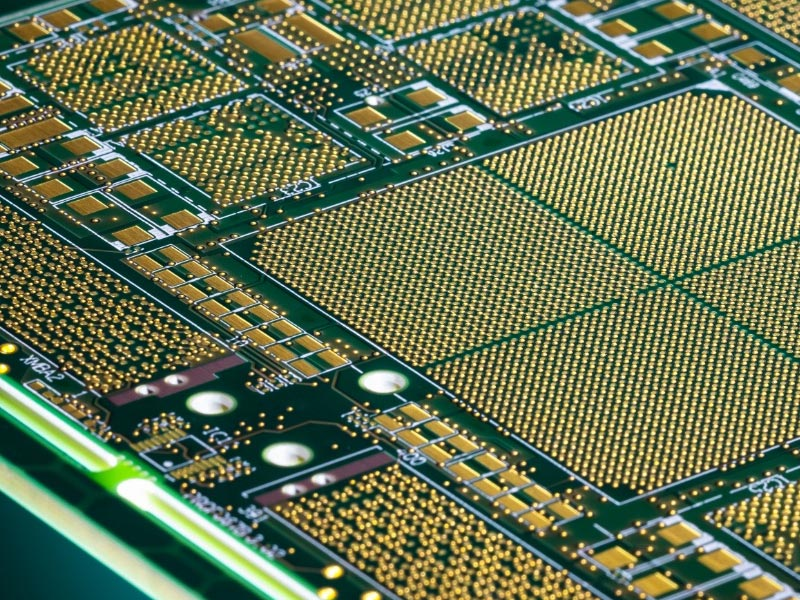

I-Copper yeyona ngxubevange ikhethwayo kuba inokuthumela imiqondiso yombane kuyo yonke indawo ngaphandle kweengxaki zokulahlekelwa okanye ukucothisa umbane. Ukusebenza kakuhle kokudluliselwa kobushushu kuvumela abavelisi ukuba bafake ii-heat sinks zakudala kumphezulu. I-Copper ngokwayo iyasebenza, njengoko i-ounce yobhedu inokugubungela i-PCB substrate engama-square foot kwi-1.4 thousandths ye-intshi okanye i-35 micrometers ubukhulu.

I-Copper inamandla kakhulu okuhambisa umbane kuba ine-electron ekhululekileyo enokuhamba ukusuka kwi-atom enye ukuya kwenye ngaphandle kokucotha. Ngenxa yokuba ihlala isebenza kakuhle kuloo nqanaba lincinci kakhulu njengoko isenza kumanqanaba atyebileyo, i-copper encinci iyanceda kakhulu.

Ubhedu kunye nezinye izinyithi ezixabisekileyo ezisetyenziswa kwi-PCBs

Uninzi lwabantu lubona ii-PCB njengezo ziluhlaza. Kodwa, zihlala zinemibala emithathu kumaleko wangaphandle: igolide, isilivere, kunye nobomvu. Zikwanobhedu olucocekileyo ngaphakathi nangaphandle kwe-PCB. Ezinye izinyithi ezikwibhodi yesekethe zibonakala ngemibala eyahlukeneyo. Umaleko wegolide ngowona ubiza kakhulu, umaleko wesilivere unexabiso lesibini eliphezulu, kwaye ubomvu ngumaleko ongabizi kakhulu.

Ukusebenzisa iGolide yokuntywiliselwa kwi-PCBs

ubhedu kwibhodi yesekethe eprintiweyo

Umaleko ogqunywe ngegolide usetyenziselwa iziqwenga zokudibanisa kunye nee-component pads. Umaleko wegolide ontywilisiweyo ukho ukuthintela ukufuduka kwee-athomu eziphezulu. Umaleko awungombala wegolide kuphela, kodwa wenziwe ngegolide yokwenyani. Igolide incinci kakhulu kodwa yanele ukwandisa ubomi bezinto ezifuna ukudityaniswa. Igolide ithintela iindawo ze-solder ukuba zingadli ngokuhamba kwexesha.

Ukusebenzisa iSilivere yokuntywiliselwa kwi-PCBs

Isilivere yenye yentsimbi esetyenziswa ekwenzeni iiPCB. Ixabiso layo liphantsi kakhulu kunokuntywiliselwa kwegolide. Ukuntywiliselwa kwesilivere kungasetyenziswa endaweni yokuntywiliselwa kwegolide kuba kukwanceda ekuqhagamshelweni, kwaye kunciphisa iindleko zizonke zebhodi. Ukuntywiliselwa kwesilivere kudla ngokusetyenziswa kwiiPCB ezisetyenziswa kwiimoto nakwizixhobo zekhompyutha.

I-Copper Clad Laminate kwii-PCB

Endaweni yokusebenzisa ukuntywiliselwa, ithusi lisetyenziswa ngendlela egqunyiweyo. Le yimaleko ebomvu yePCB, kwaye yeyona ntsimbi isetyenziswa kakhulu. I-PCB yenziwe ngethusi njengesinyithi esisisiseko, kwaye kuyimfuneko ukwenza iisekethe ziqhagamshelane kwaye zithethelane ngempumelelo.

Isetyenziswa Njani I-Copper Foil kwi-PCBs?

I-Copper ineendlela ezininzi ezisetyenziswayo kwi-PCB, ukusuka kwi-laminate egqunywe yi-copper ukuya kwii-traces. I-Copper ibalulekile ukuze ii-PCB zisebenze ngokufanelekileyo.

Yintoni i-PCB Trace?

Isandi se-PCB yindlela evakala ngayo, indlela eya kulandelwa yisekethe. Isandi siquka inethiwekhi yobhedu, iingcingo, kunye nobushushu, kunye neefusi kunye nezinto ezisetyenziswa ebhodini.

Eyona ndlela ilula yokuqonda umkhondo kukucinga ngawo njengendlela okanye ibhulorho. Ukuze ikwazi ukuthwala izithuthi, umgca kufuneka ube mkhulu ngokwaneleyo ukubamba ubuncinane ezimbini zazo. Kufuneka ube mkhulu ngokwaneleyo ukuba ungawi phantsi koxinzelelo. Kufuneka zenziwe ngezinto eziza kumelana nobunzima bezithuthi ezihamba kuwo. Kodwa, umkhondo wenza konke oku kwinqanaba elincinci kakhulu ukuhambisa umbane endaweni yeemoto.

Izinto eziyinxalenye ye-PCB Trace

Kukho izinto ezininzi ezenza umkhondo we-PCB. Zinemisebenzi eyahlukeneyo ekufuneka yenziwe ukuze ibhodi yenze umsebenzi wayo ngokufanelekileyo. Ubhedu kufuneka lusetyenziswe ukunceda uthotho lwenze imisebenzi yalo, kwaye ngaphandle kwe-PCB, besingayi kuba nazo naziphi na izixhobo zombane. Khawuthelekelele ihlabathi elingenazo ii-smartphones, iilaptops, abenzi bekofu, kunye neemoto. Yiloo nto besinokuba nayo ukuba ii-PCB bezingayisebenzisi i-copper.

Ubukhulu bePCB Trace

Uyilo lwe-PCB luxhomekeke kubukhulu bebhodi. Ubukhulu buya kuchaphazela ibhalansi kwaye buya kugcina izixhobo zidibene.

Ububanzi be-PCB Trace

Ububanzi bomkhondo bubalulekile. Oku akuchaphazeli ibhalansi okanye ukuncamathiselwa kwezixhobo, kodwa kugcina umsinga udlula ngaphandle kokutshisa kakhulu okanye ukonakalisa ibhodi.

I-PCB Trace yangoku

Umsinga wokulandelela we-PCB uyimfuneko kuba yile nto isetyenziswa yibhodi ukuhambisa umbane kwiinxalenye kunye neengcingo. Ubhedu lunceda oku kwenzeke, kwaye i-elektron ekhululekileyo kwi-atom nganye yenza ukuba umsinga uhambe kakuhle phezu kwebhodi.

Kutheni iCopper Foil ikwiPCB?

Inkqubo yokwenza ii-PCB

Inkqubo yokwenza i-PCB iyafana. Ezinye iinkampani ziyenza ngokukhawuleza kunezinye, kodwa zonke zisebenzisa inkqubo kunye nezixhobo ezifanayo. La manyathelo:

Yenza isiseko nge-fiberglass kunye ne-resin

Beka iileya zobhedu kwisiseko

Chonga kwaye usete iipateni zobhedu

Hlamba ibhodi ebhafini

Yongeza imaski yesolder ukukhusela iPCB

Ncamathisela i-silkscreen kwi-PCB

Beka kwaye udibanise ii-resistor, ii-integrated circuits, ii-capacitors, kunye nezinye izinto

Vavanya i-PCB

IiPCB kufuneka zibe nezinto ezikhethekileyo kakhulu ukuze zisebenze ngokufanelekileyo. Enye yezona zinto zibalulekileyo kwiPCB yikopolo. Le ngxube iyimfuneko ukuqhuba umbane kwizixhobo eziza kufakwa kuzo iiPCB. Ngaphandle kobhedu, izixhobo aziyi kusebenza kuba umbane awuyi kuba nengxube yokuhamba.

Ixesha lokuthumela: Epreli-25-2022