Ifoyile yekopoloinesantya esiphantsi seoksijini engaphezulu kwaye inokudityaniswa neendidi ezahlukeneyo zezinto ezisetyenziswayo, ezifana nesinyithi, izinto zokukhusela. Kwaye ifoyile yobhedu isetyenziswa kakhulu ekukhuseleni nge-electromagnetic kunye ne-antistatic. Ukubeka ifoyile yobhedu eqhubayo kumphezulu we-substrate kwaye idityaniswe ne-substrate yesinyithi, iya kubonelela ngokuqhubekeka okuhle kunye nokukhusela nge-electromagnetic. Ingahlulwahlulwa ibe: ifoyile yobhedu ezinamathelayo, ifoyile yobhedu esecaleni elinye, ifoyile yobhedu esecaleni kabini kunye nezinye ezifana nazo.

Kule ndima, ukuba uza kufunda ngakumbi nge-copper foil kwinkqubo yokwenziwa kwe-PCB, nceda ujonge kwaye ufunde umxholo ongezantsi kule ndima ukuze ufumane ulwazi oluthe kratya malunga nobungcali.

Zithini iimpawu zefoyile yobhedu kwimveliso yePCB?

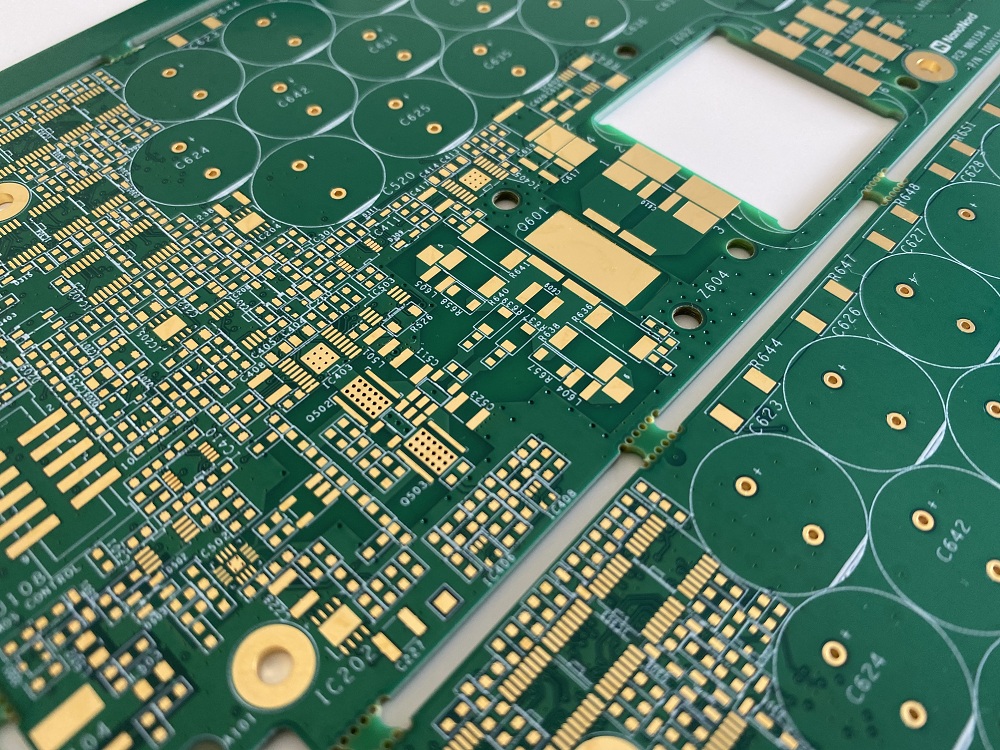

Ifoyile yobhedu yePCBbubukhulu bokuqala bobhedu obusetyenziswa kumaleko angaphandle nangaphakathi ebhodi yePCB enamaleko amaninzi. Ubunzima bobhedu buchazwa njengobunzima (ngee-ounces) bobhedu obukhoyo kwindawo enye yesikwere seenyawo. Le parameter ibonisa ubukhulu bobhedu obupheleleyo kumaleko. I-MADPCB isebenzisa ubunzima bobhedu obulandelayo ekwenzeni i-PCB (ipleyiti yangaphambili). Ubunzima obulinganiswa kwi-oz/ft2. Ubunzima bobhedu obufanelekileyo bunokukhethwa ukuze buhambelane neemfuno zoyilo.

· Kwimveliso ye-PCB, iifoyile zekopolo zikwimiqolo, ezikumgangatho we-elektroniki kunye nobumsulwa be-99.7%, kunye nobukhulu be-1/3oz/ft2 (12μm okanye 0.47mil) – 2oz/ft2 (70μm okanye 2.8mil).

· I-copper foil inezinga eliphantsi le-oksijini engaphezulu kwaye ingaqhotyoshelwa kwangaphambili ngabavelisi be-laminate kwizinto ezahlukeneyo ezisisiseko, ezifana ne-metal core, i-polyimide, i-FR-4, i-PTFE kunye ne-ceramic, ukuvelisa ii-laminate ezifakwe i-copper clad.

· Ingafakwa nakwibhodi enezitezi ezininzi njengefoyile yobhedu ngokwayo ngaphambi kokuba icinezelwe.

· Kwimveliso ye-PCB eqhelekileyo, ubukhulu bokugqibela bobhedu kwiileya zangaphakathi buhlala buyi-foil yobhedu yokuqala; Kwiileya zangaphandle sibeka ubhedu olongezelelweyo oluyi-18-30μm kwiindlela ngexesha lenkqubo yokuplata iipaneli.

· Ubhedu lwemaleko angaphandle eebhodi ezinee-multilayer lukwimo yefoyile yobhedu kwaye lucinezelwe kunye nee-prepregs okanye ii-cores. Ukuze lusetyenziswe ngee-microvias kwi-HDI PCB, ifoyile yobhedu ikwi-RCC ngqo (i-resin coated copper).

Kutheni kufuneka i-copper foil kwimveliso ye-PCB?

Ifoyile yobhedu ye-elektroniki (ubumsulwa obungaphezulu kwe-99.7%, ubukhulu obuyi-5um-105um) yenye yezinto ezisisiseko kushishino lwe-elektroniki. Uphuhliso olukhawulezileyo kushishino lolwazi lwe-elektroniki, ukusetyenziswa kwefoyile yobhedu ye-elektroniki kuyanda, iimveliso zisetyenziswa kakhulu kwiikhalkhuleyitha zoshishino, izixhobo zonxibelelwano, izixhobo ze-QA, iibhetri ze-lithium-ion, iiseti zikamabonwakude eziqhelekileyo, iirekhoda zevidiyo, abadlali beCD, iikopi, ifowuni, i-air conditioning, ii-elektroniki zeemoto, ii-consoles zemidlalo.

Ifoyile yobhedu yemizi-mvelisoinokwahlulwahlulwa ibe ziindidi ezimbini: i-rolled copper foil (RA copper foil) kunye ne-point copper foil (ED copper foil), apho i-calendaring copper foil ine-ductility elungileyo kunye nezinye iimpawu, yinkqubo yokuqala yepleyiti ethambileyo esetyenzisiweyo i-Copper foil, ngelixa i-electrolytic copper foil iyindleko ephantsi yokwenza i-copper foil. Njengoko i-rolling copper foil iyinto ebalulekileyo eluhlaza yebhodi ethambileyo, ngoko ke iimpawu ze-calendaring copper foil kunye notshintsho lwamaxabiso kushishino lwebhodi ethambileyo zinempembelelo ethile.

Ziziphi imithetho esisiseko yoyilo lwe-copper foil kwi-PCB?

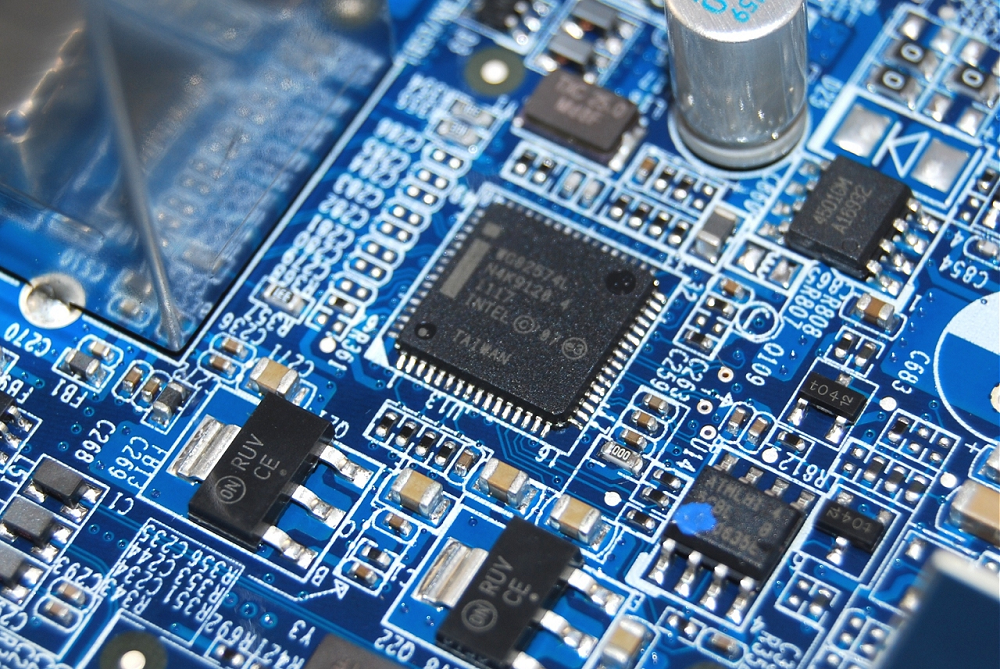

Uyazi na ukuba iibhodi zesekethe eziprintiweyo zixhaphake kakhulu kwiqela lee-elektroniki? Ndiqinisekile ukuba kukho enye kwisixhobo se-elektroniki osisebenzisayo ngoku. Nangona kunjalo, ukusebenzisa ezi zixhobo ze-elektroniki ngaphandle kokuqonda itekhnoloji yazo kunye nendlela yokuyila nayo yinto eqhelekileyo. Abantu basebenzisa izixhobo ze-elektroniki rhoqo ngeyure kodwa abazi ukuba zisebenza njani. Nazi ezinye zezona ndawo ziphambili ze-PCB ezikhankanyiweyo ukuba zinokuqonda ngokukhawuleza indlela ezisebenza ngayo iibhodi zesekethe eziprintiweyo.

· Ibhodi yesekethe eprintiweyo yibhodi yeplastiki elula eyongeziweyo ngeglasi. Ifoyile yobhedu isetyenziselwa ukulandelela iindlela kwaye ivumela ukuhamba kweetshaja kunye nemiqondiso ngaphakathi kwesixhobo. Iitshaja zobhedu yindlela yokubonelela ngamandla kwiindawo ezahlukeneyo zesixhobo sombane. Endaweni yeengcingo, iitshaja zobhedu zikhokela ukuhamba kweetshaja kwi-PCBs.

· IiPCB zinokuba ngumaleko omnye kunye nomaleko amabini. I-PCB enye eneeleya zezona zilula. Zine-foil yobhedu kwelinye icala kwaye elinye icala ligumbi lezinye izinto. Ngelixa kwi-PCB eneeleya ezimbini, omabini amacala agcinelwe i-foil yobhedu. Ii-PCB ezineeleya ezimbini ziyinkimbinkimbi ezinee-traces ezinzima zokuhamba kwee-charges. Akukho foil yobhedu inokuwelana. Ezi PCB ziyafuneka kwizixhobo ze-elektroniki ezinzima.

· Kukwakho neengqimba ezimbini zeesolders kunye ne-silkscreen kwi-PCB yobhedu. I-solder mask isetyenziselwa ukwahlula umbala we-PCB. Kukho imibala emininzi yee-PCB ezikhoyo ezifana noluhlaza, umfusa, ubomvu, njl. I-solder mask ikwachaza ubhedu kwezinye iintsimbi ukuze kuqondwe ubunzima bonxibelelwano. Nangona i-silkscreen iyinxalenye yombhalo we-PCB, oonobumba kunye namanani ahlukeneyo abhalwa kwi-silkscreen yomsebenzisi kunye nonjineli.

Ungayikhetha njani into efanelekileyo yefoyile yobhedu kwi-PCB?

Njengoko bekutshiwo ngaphambili, kufuneka ubone indlela yenyathelo ngenyathelo yokuqonda ipateni yokwenziwa kwebhodi yesekethe eprintiweyo. Ukwenziwa kwezi bhodi kuqulathe iileya ezahlukeneyo. Masiqonde oku ngokulandelelana:

Izinto ezingaphantsi komhlaba:

Isiseko esisezantsi phezu kwebhodi yeplastiki esetyenziswa ngeglasi yi-substrate. I-substrate sisakhiwo se-dielectric sephepha elenziwe ngee-epoxy resins kunye nephepha leglasi. I-substrate yenzelwe ngendlela yokuba ikwazi ukuhlangabezana neemfuno umzekelo i-transition temperature (TG).

Ukucoca:

Njengoko kucacile kwigama, i-lamination ikwayindlela yokufumana iipropati ezifunekayo ezifana nokwandiswa kobushushu, amandla okucheba, kunye nobushushu bokuguquka (TG). I-lamination yenziwa phantsi koxinzelelo oluphezulu. I-lamination kunye ne-substrate kunye zidlala indima ebalulekileyo ekuhambeni kweetshaja zombane kwi-PCB.

Ixesha lokuthumela: Juni-02-2022