Uhlu lwe-ED copper foil:

1. Ngokwendlela esebenza ngayo, i-ED copper foil inokwahlulwa ibe ziintlobo ezine: STD, HD, HTE kunye ne-ANN

2. Ngokweendawo eziphezulu,Ifoyile yobhedu ye-EDZinokwahlulwa zibe ziintlobo ezine: akukho nyango lomphezulu kwaye akukho thintelo lomhlwa, unyango lomphezulu lokulwa nokugqwala, ulungiso lwecala elinye lokulwa nokugqwala kunye nokujongana kabini nothintelo lomhlwa.

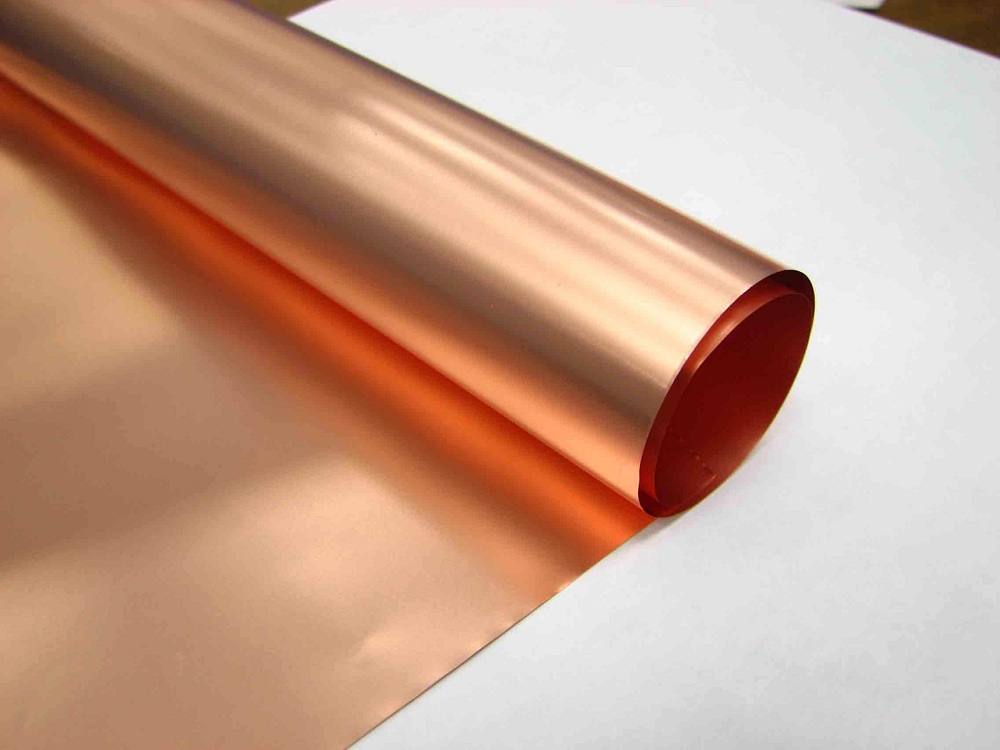

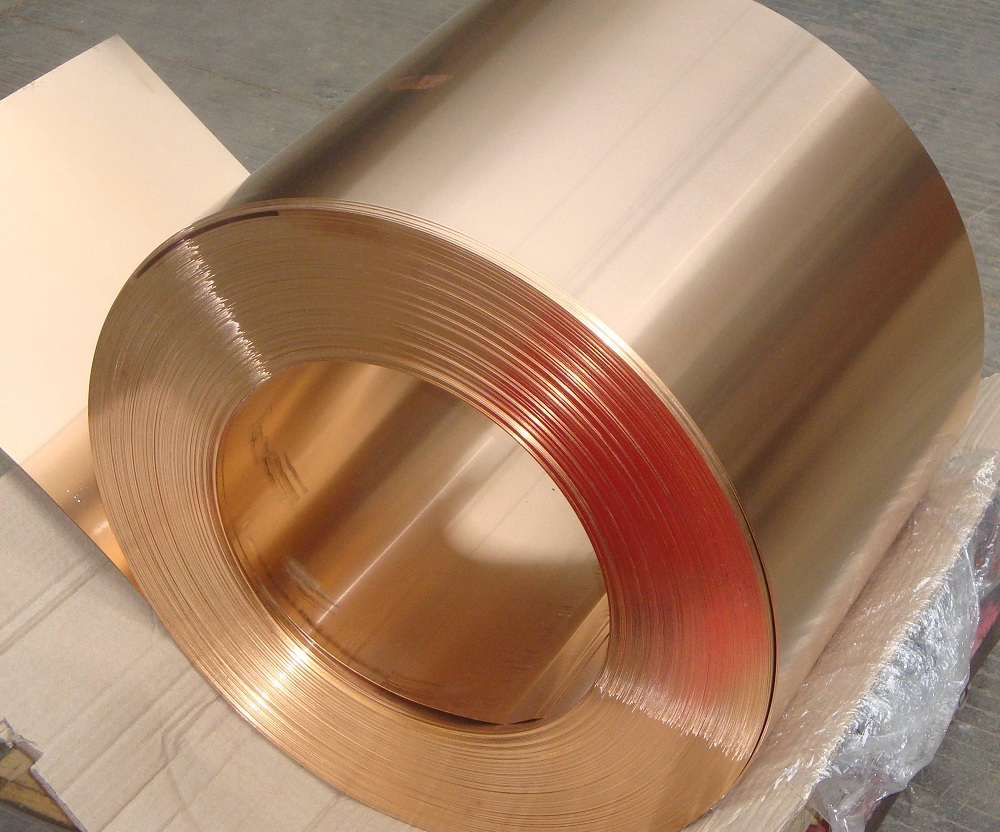

Ukusuka kwicala lobukhulu, ubukhulu obuqhelekileyo obungaphantsi kwe-12μm yi-foil yobhedu ebhityileyo ye-electrolytic. Ukuze kuthintelwe impazamo ekulinganisweni kobukhulu, kunye nobunzima kwindawo nganye yeyunithi kubonakaliswa njenge-foil yobhedu ye-electrolytic ye-18 kunye ne-35μm, ubunzima bayo obunye buhambelana ne-153 kunye ne-305g / m2. Imigangatho yomgangatho wefoil yobhedu ye-ED kuquka ubumsulwa befoil yobhedu ye-electrolytic, ukumelana noxinzelelo, amandla, ukunwebeka, amandla okuwelda, ukubola, uburhabaxa bomphezulu, njl.

3.Ifoyile yobhedu ye-EDinokwahlulwa ibe yinkqubo yemveliso yokulungiselela isisombululo se-electrolytic, i-electrolysis kunye ne-post-processing ngokwetekhnoloji yokuvelisa i-electrolytic copper foil.

Ukulungiswa kwe-electrolyte:

Okokuqala, beka ubunyulu obungaphezulu kwe-99.8% yezinto zobhedu emva kokususa amafutha kwi-copper dissolved tank; emva koko upheke nge-sulfuric acid uvuselela kwaye sifumana i-copper sulfate enyibilikisiweyo. Faka i-copper sulfate kwi-reservoir xa uxinzelelo lufikelela kwiimfuno. Kuya kuza inkqubo yokujikeleza kwesisombululo ngepayipi kunye ne-pump reservoir kunye ne-cell Unicom. Emva kokuba ukujikeleza kwesisombululo kuzinzile, kunokunika amandla i-electrolysis cell. I-Electrolyte kufuneka yongeze ubungakanani obufanelekileyo be-surfactant ukuqinisekisa amaxabiso e-particle copper, i-Crystal orientation, i-roughness, i-porosity, kunye nezinye izalathisi.

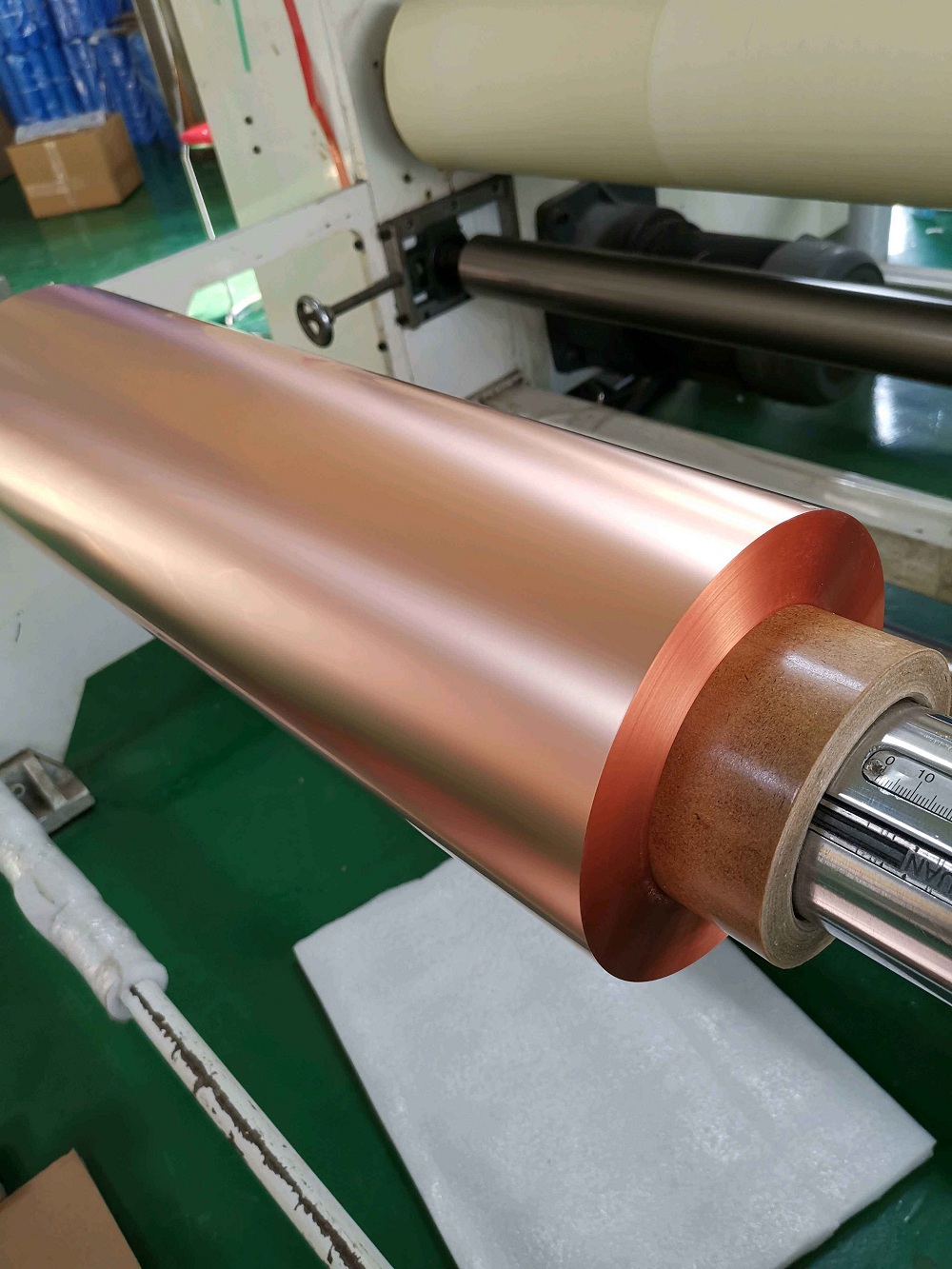

Inkqubo ye-electrodes kunye ne-electrolysis

I-Electrolysis cathode sisigubhu esijikelezayo, esibizwa ngokuba yi-cathode roll. Kwaye ingasebenzisa umcu wesinyithi ongenantloko ofumanekayo njenge-cathode. Iqala ukufakwa kwi-copper cathode emva kwamandla. Ke ngoko, ububanzi bevili kunye nebhanti kumisela ububanzi be-electrolytic copper foil; kwaye isantya esijikelezayo okanye esihambayo simisela ubukhulu be-electrolytic copper foil. I-Copper efakwe kwi-cathode iyaqhubeka nokuxotyulwa, icocwe, yomiswe, isikwe, ijikelezwe kwaye ivavanywe emva konyango oluthunyelwe kubafaki-zicelo abaphumeleleyo. I-electrolysis anode ayinyibiliki kwi-lead okanye i-lead alloy.

Ipharamitha yenkqubo ayinxulunyaniswanga kuphela nesantya se-electrolysis kwi-cathode, kodwa ikwanxulumene nesisombululo se-electrolyte okanye uxinzelelo, ubushushu, kunye noxinano lwangoku lwe-cathode ngexesha le-electrolysis.

Ipharamitha yenkqubo ayinxulunyaniswanga kuphela nesantya se-electrolysis kwi-cathode, kodwa ikwanxulumene nesisombululo se-electrolyte okanye uxinzelelo, ubushushu, kunye noxinano lwangoku lwe-cathode ngexesha le-electrolysis.

Irola ye-titanium cathode ejikelezayo:

Ngenxa yokuba i-titanium inamandla aphezulu ekhemikhali kwaye inamandla aphezulu. Ikrazula ngokulula kumphezulu oqengqelekayo kwaye ine-porosity ephantsi ye-electrolytic copper foil. I-titanium cathode kwinkqubo ye-electrolytic iya kuvelisa i-passive phenomenon, ngoko ke ifuna ukucocwa rhoqo, ukugaywa, ukupolishwa, i-nickel, i-chrome. Izithinteli zokubola zingongezwa, ezifana ne-nitro okanye i-nitrous aromatic okanye i-aliphatic compounds kwi-electrolyte, izinga lokudlula linciphisa i-titanium cathode. Kwakhona ezinye iinkampani zisebenzisa i-cathode yentsimbi engagqwaliyo ukunciphisa iindleko.

Ixesha lokuthumela: Jan-09-2022