Ngenxa yokuba inomtsalane omkhulu kwiintlobo ngeentlobo zeemveliso zoshishino, ubhedu lubonwa njengento enokusebenziseka lula kakhulu.

Iifoyile zekopolo ziveliswa ziinkqubo ezithile zokwenza izinto ngaphakathi kwifektri yefoyile ezibandakanya ukuqengqeleka okushushu nokubandayo.

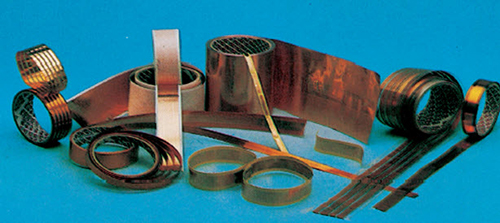

Kunye ne-aluminium, ubhedu lusetyenziswa kakhulu kwiimveliso zoshishino njengezinto ezinokuguquguquka kakhulu phakathi kwezinto zesinyithi ezingenayo i-ferrous. Ingakumbi kwiminyaka yakutshanje, imfuno ye-copper foil ibikhula kakhulu kwiimveliso ze-elektroniki kuquka iifowuni eziphathwayo, iikhamera zedijithali, kunye nezixhobo ze-IT.

Ukwenziwa kwefoyile

Iifoyile zobhedu ezibhityileyo ziveliswa ngokubeka i-electrodeposition okanye ngokuqengqeleka. Kwindawo yokufaka i-electrode, ubhedu olukumgangatho ophezulu kufuneka lunyibilikiswe kwi-asidi ukuze kuveliswe i-electrolyte yobhedu. Esi sisombululo se-electrolyte sipompelwa kwiidrama ezintywilisiweyo kancinci, ezijikelezayo ezitshajwa ngombane. Kwezi drum, ifilimu encinci yobhedu ifakwa i-electrodeposition. Le nkqubo ikwaziwa ngokuba yi-plating.

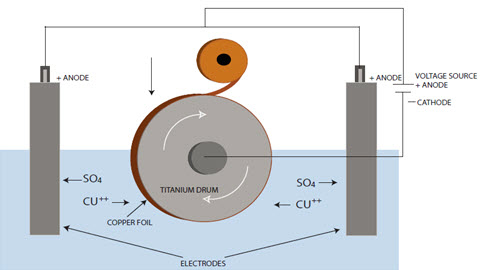

Kwinkqubo yokwenziwa kobhedu olufakwe kwi-electrodeposition, i-copper foil ifakwa kwi-titanium rotating drum evela kwisisombululo sobhedu apho iqhagamshelwe kumthombo we-DC voltage. I-cathode inamathele kwi-drum kwaye i-anode ifakwa kwisisombululo se-copper electrolyte. Xa kusetyenziswa intsimi yombane, i-copper ifakwa kwi-drum njengoko ijikeleza ngesantya esicothayo kakhulu. Umphezulu wobhedu kwicala le-drum uthambile ngelixa icala elichaseneyo lirhabaxa. Okukhona isantya se-drum sicotha, kokukhona i-copper iba nkulu kwaye ngokuchaseneyo. I-copper iyatsalwa kwaye iqokeleleke kumphezulu we-cathode we-titanium drum. Icala le-matte kunye ne-drum le-copper foil lidlula kwimijikelo eyahlukeneyo yonyango ukuze i-copper ifaneleke kwi-PCB. Unyango luphucula ukunamathelana phakathi kwe-copper kunye ne-dielectric interlayer ngexesha lenkqubo ye-copper clad lamination. Enye inzuzo yonyango kukusebenza njenge-anti-tarnish agents ngokunciphisa i-oxidation ye-copper.

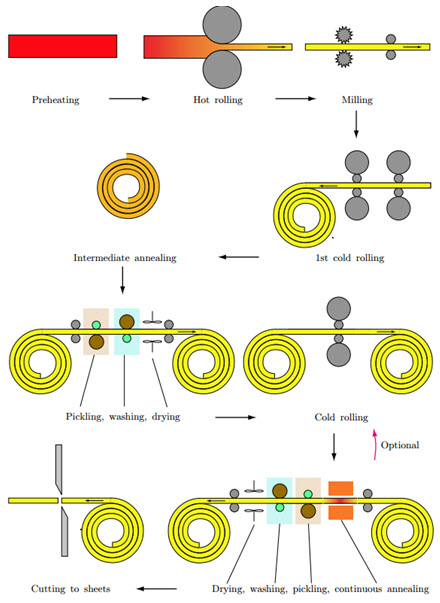

Umfanekiso 1:Inkqubo Yokwenza Ubhedu Olufakwe Nge-Electrodeposited Umfanekiso 2 ubonisa iinkqubo zokwenza iimveliso zobhedu ezigoqiweyo. Izixhobo zokugoqa zahlulwe zibe ziintlobo ezintathu; ezizezi, ii-hot rolling mills, ii-cold rolling mills, kunye nee-foil mills.

Iikhoyili zeefoyile ezibhityileyo zenziwa kwaye ziphathwe ngeekhemikhali nangoomatshini de zenziwe zibe yimo yazo yokugqibela. Inkcazo-bume yenkqubo yokuqengqeleka kweefoyile zobhedu inikwe kuMfanekiso 2. Ibhloko yobhedu oluphosiweyo (ubukhulu obuqikelelweyo: 5mx1mx130mm) itshiswa ukuya kuthi ga kwi-750°C. Emva koko, itshiswe ngobushushu ngokuguquguquka ngamanyathelo aliqela ukuya kuthi ga kwi-1/10 yobukhulu bayo bokuqala. Ngaphambi kokuba kuqengqeleke ubushushu bokuqala, izikali ezivela ekunyangweni kobushushu zisuswa ngokusila. Kwinkqubo yokuqengqeleka ebandayo ubukhulu buncitshiswa bube malunga ne-4 mm kwaye amaphepha enziwe abe ziikhoyili. Inkqubo ilawulwa ngendlela yokuba izinto zikhule kuphela kwaye azitshintshi ububanzi bazo. Njengoko amaphepha engenakwenziwa ngakumbi kule meko (izinto zinomsebenzi oqinileyo kakhulu) afumana unyango lobushushu kwaye afudunyezwa ukuya kuthi ga kwi-550°C.

Ixesha lokuthumela: Agasti-13-2021