Ngenxa yophuhliso olukhawulezileyo lweemarike zezithuthi zombane kunye nezixhobo ezinxitywayo, ukugcina ukusebenza kwebhetri kwiindawo ezinobushushu obuphantsi kuye kwaba yinto ebalulekileyo ngakumbi. Iipleyiti zokufudumeza iibhetri zidlala indima ebalulekileyo ekuqinisekiseni ukusebenza kwebhetri, ubomi bayo, kunye nokhuseleko kwimozulu ebandayo. Kule meko, i-copper foil iveliswa yiIsinyithi Esiyilwe Ngomoyaidlala indima ebaluleke kakhulu.

I. Ipleyiti yokufudumeza yebhetri sisixhobo esisetyenziselwa ukugcina ubushushu obufanelekileyo bokusebenza kweebhetri kwiindawo ezinobushushu obuphantsi. Isetyenziswa kakhulu kwizithuthi zombane, izithuthi ezixutyiweyo, kunye nezinye izixhobo ze-elektroniki ezifuna ulawulo oluzinzileyo lobushushu bebhetri. Nantsi inkcazo eneenkcukacha ngomgaqo wokusebenza kwepleyiti yokufudumeza yebhetri:

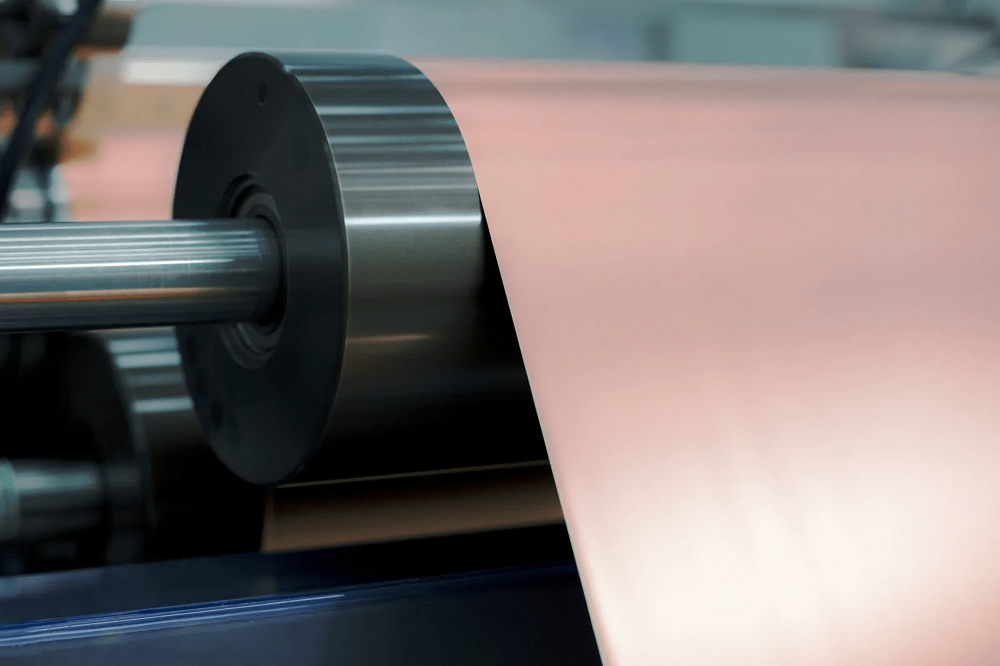

Ipleyiti yokufudumeza yebhetri ngokuyintloko iqulathe izinto zokufudumeza, izinto eziqhuba ubushushu (ezifana ne-copper foil), kunye nezinto zokukhusela ubushushu. Izinto zokufudumeza, ezinokuba ziintambo zokumelana, izinto zePositive Temperature Coefficient (PTC), okanye ii-flexible thin film heaters, zinoxanduva lokuvelisa ubushushu.

Xa umbane unikezelwa kwipleyiti yokufudumeza yebhetri, izinto zokufudumeza ziqala ukuvelisa ubushushu. Olu bushushu luqhutywa ngezinto eziqhuba ubushushu (umz., i-copper foil). Ubushushu obuphezulu be-copper foil buqinisekisa ukuba ubushushu busasazwa ngokukhawuleza nangokulinganayo kuyo yonke ipleyiti yokufudumeza.

Njengoko ubushushu buqhutywa, ubushushu bepleyiti yokufudumeza yebhetri buyanda kancinci kancinci. Izinto zokukhusela ubushushu zithintela ukulahleka kobushushu kwaye ziqinisekisa ukuba ubushushu buqhutywa kuphela kwiindawo ezifunekayo.

Ipleyiti yokufudumeza ibhetri isondelelene nebhetri (okanye ipakethi yebhetri), idlulisela ubushushu ukuze kugcinwe ubushushu obufanelekileyo bokusebenza kwebhetri kwiindawo ezibandayo. Oku kunceda ukuqinisekisa ukusebenza kakuhle kwebhetri, ixesha layo lokuphila, kunye nokhuseleko.

Ukuze kufezekiswe ulawulo oluchanekileyo lobushushu, ipleyiti yokufudumeza yebhetri idla ngokuxhotyiswa ngee-sensors zobushushu kunye nesilawuli. Ii-sensors zobushushu zibona ubushushu bebhetri ngexesha langempela kwaye zithumele idatha kumlawuli. Isilawuli silungisa amandla okukhupha ipleyiti yokufudumeza ngokusekelwe kubushushu obufunekayo, ukuqinisekisa ukuba ibhetri isebenza ngaphakathi koluhlu lobushushu olufanelekileyo.

Ngamafutshane, ipleyiti yokufudumeza yebhetri isebenza ngokuguqula amandla ombane abe ngamandla obushushu kwaye isebenzise ukuhanjiswa kobushushu okuphezulu kwezinto ezifana ne-copper foil ukubonelela ngobushushu obungaguqukiyo nobufanayo kwibhetri, ukuqinisekisa ukusebenza kwayo okuqhelekileyo kwiindawo ezinobushushu obuphantsi.

II. Iingenelo ze-CIVEN METAL copper foil kwiipleyiti zokufudumeza zebhetri

Ukuqhuba okuphezulu kobushushu:Isinyithi Esiyilwe NgomoyaI-copper foil inika ukuhanjiswa kobushushu okugqwesileyo, iqinisekisa ukudluliselwa kobushushu ngokukhawuleza nangokulinganayo kwibhetri, nto leyo eyandisa ukusebenza kakuhle kwepleyiti yokufudumeza.

Izinto eziluhlaza ezicocekileyo kakhulu: I-CIVEN METAL copper foil, eyenziwe ngezinto zobhedu ezicocekileyo kakhulu, ibonakalisa ukumelana okugqwesileyo kwe-oxidation, iqinisekisa ukusebenza okuzinzileyo kwepleyiti yokufudumeza yebhetri.

Iinkqubo zemveliso eziphambili: Ngeminyaka yobuchwephesha kunye nezixhobo zemveliso eziphambili kwihlabathi liphela, i-CIVEN METAL ivelisa iimveliso zefoyile yobhedu ezihambelanayo kakhulu.

Iinkonzo ezenzelwe wena: I-CIVEN METAL inikezela ngeemveliso zefoyile yobhedu ezenzelwe wena ezilungiselelwe iimfuno zabathengi, ezihlangabezana neemfuno zezicelo ezahlukeneyo.

Inkxaso yobuchwephesha yobungcali kunye nenkonzo yasemva kokuthengisa: I-CIVEN METAL ineqela lobuchwephesha elinamava, elibonelela ngenkxaso yobugcisa epheleleyo kunye nenkonzo yasemva kokuthengisa kubathengi, ukuqinisekisa ukusetyenziswa okungenaxhala.

Ukuququmbela,Isinyithi Esiyilwe NgomoyaI-copper foil idlala indima ebalulekileyo kwicandelo leepleyiti zokufudumeza zebhetri, ibonelela ngezisombululo zokulawula ubushushu ezisebenzayo nezithembekileyo kwizithuthi zombane kunye nezixhobo ezinxitywayo. Izixhobo ezisemgangathweni ophezulu, iinkqubo zemveliso eziphambili, ulawulo oluqinileyo lomgangatho, kunye nenkonzo ebalaseleyo emva kokuthengisa ifumene i-CIVEN METAL udumo olukhulu kwimarike yehlabathi.

Njengoko iimarike zamandla ahlaziyekayo kunye nezixhobo ezikrelekrele ziqhubeka nokukhula, i-CIVEN METAL iza kutyala imali kuphando nophuhliso kunye nophuhliso lwetekhnoloji ukubonelela ngemveliso yefoyile yobhedu ekumgangatho ophezulu kubathengi kunye nokuxhasa ukuqhubela phambili kwetekhnoloji yepleyiti yokufudumeza yebhetri. Ngemizamo ye-CIVEN METAL, ikamva letekhnoloji yepleyiti yokufudumeza yebhetri ngokungathandabuzekiyo liqaqambile.

Ixesha lokuthumela: Meyi-09-2023