Ukudala ubugcisa beglasi enemibala engafaniyo kunokuba nzima, ingakumbi kwabo baqalayo. Ukukhetha i-foil yobhedu engcono kuxhomekeka kwizinto ezininzi ezifana nobukhulu kunye nobukhulu be-foil. Okokuqala awufuni ukufumana i-foil yobhedu engahambelani neemfuno zeprojekthi.

Iingcebiso zokukhetha i-copper foil efanelekileyo

Ngethamsanqa,Isinyithi seCivenineembono ezintle eziluncedo xa uthenga i-copper foil efanelekileyo kodwa elula ukuyisebenzisa kwiprojekthi ekhoyo. Zeziphi izinto ezibalulekileyo ekufuneka uziqwalasele xa ukhetha i-copper foil efanelekileyo yeglasi enombala omdaka? Siza kujonga ezinye izinto ekufuneka uziqwalasele ngaphambi kokuba uthenge i-copper foil efanelekileyo kwiprojekthi yeglasi engcolileyo.

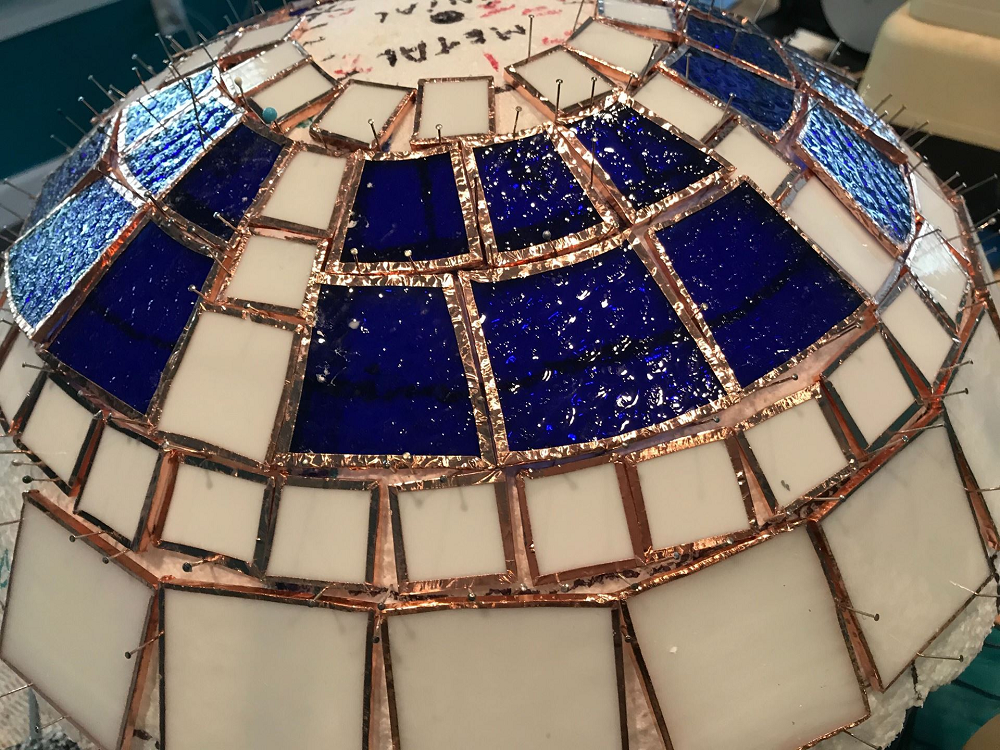

Ubungakanani beprojekthi

Ubungakanani beprojekthi buchaza ubungakanani befoyile yobhedu efanelekileyo ukusetyenziswa. Ifoyile yobhedu eyi-3/16″ okanye i-1/4″ ilungele ukusetyenziswa kweglasi. Iifoyile ezibanzi kakhulu kunolu luhlu zihlala zinzima xa zifakelwa. Nokuba zisetyenziselwa iiphaneli zeglasi ezinkulu, iifoyile ezibanzi azisebenzi kakuhle. Ukuqwalasela ubungakanani beprojekthi ekhoyo kubalulekile xa ukhetha ifoyile yobhedu efanelekileyo yeglasi enemibala eyomileyo. I-Civec Metal ibonelela ngeefoyile zobhedu zobukhulu obahlukeneyo ukuze zilungele zonke iiprojekthi.

Ububanzi befoyile yobhedu

Iifoyile zekopoloezishiya imigca emincinci ingasebenzi kwaye iqinile. Oku kungenxa yokuba i-solder eyongezelelweyo ingafakwa kwisinyithi. Uninzi lwabaculi bakhetha ukusebenzisa i-foil ye-7/32″ kodwa ukuba utshintsha ububanzi be-foil yobhedu, kufuneka ubunzulu obungakumbi. Iglasi etyebileyo kakhulu ifuna i-foil yobubanzi be-¼”. Ukuze usebenzise iziphumo ezongezelelweyo, kububulumko ukunqumla i-foil usebenzisa i-razor blade ebukhali. Kwakhona, ukwenza umgama kwiprojekthi yakho yomsebenzi akuyondlwan 'iyaphela njengoko imigca ye-foil iyancipha ngokuhamba kwexesha. Ukuze ufezekise oku, i-foil ye-5/32″ okanye ye-3/16″ ifanelekile xa wongeza izinto zokugqibela.

Ubukhulu befoyile yekopolo

Ifoyile yekopoloidla ngokulinganiswa ngokwee-mils. Lumka ukuba iifoyile zekopolo ezingabizi kakhulu zidla ngokuguguleka lula, ingakumbi xa zifakwe kwiikona. Ifoyile yobhedu yoqobo nesemgangathweni ayikrazuki kwaye ke ngoko ifanelekile kwiiprojekthi zeglasi. Ifoyile yobhedu ebhityileyo yi-1 mil kodwa uninzi lweeprojekthi zeglasi zifuna ifoyile ye-1.25 mils. Olu hlobo lwefoyile luyakwazi ukumelana nokukrazuka kwaye lufanelekile ukufakwa kwiindawo zeglasi ezigobileyo.

Uhlobo lombala wenkxaso

Ii-backings ze-copper foil ziza ngemibala emithathu eyahlukeneyo; emnyama, yesilivere, kunye ne-copper. I-backings efanelekileyo yombala kufuneka ihambelane nombala wombala we-copper foil eza kusetyenziswa. Kwi-copper patina, i-copper-backed foil yeyona ifanelekileyo ukufakwa. Ezinye iiglasi ezifana ne-opalescent azidingi mbala uthile kuba kunzima ukuyibona i-backings. Iiglasi ezikhanyayo zifuna i-backback ehambelanayo ukuze ibonakale kwaye ibonakale. Umbala weglasi kufuneka uhambelane neglasi ukuze ubonise umtsalane.

Uyilo lweprojekthi

Uyilo lweprojekthi ludlala indima ebalulekileyo xa kusongezwa izinto ozifunayo kunye nezinto ozikhethayo. Imigca enzima kwiprojekthi ifuna i-foil ebanzi kakhulu. I-foil encinci ilungile ekuboneleleni ngoyilo lweprojekthi olukhaphukhaphu.

Inkangeleko yesiqwenga seglasi

Ukusebenzisa ububanzi obahlukeneyo befoyile yobhedu kwiglasi enemibala eyohlukeneyo kunika ugxininiso olongezelelweyo, ingakumbi apho kukho ifoyile enzima. Okumangalisayo kukuba, ifoyile inika iinkcukacha ezongezelelweyo ngokwahlula imvelaphi ukusuka ngaphambili. Kwakhona, kunokwenzeka ukongeza umxholo ngelixa utsala ingqalelo enkulu kwisiqwenga seglasi.

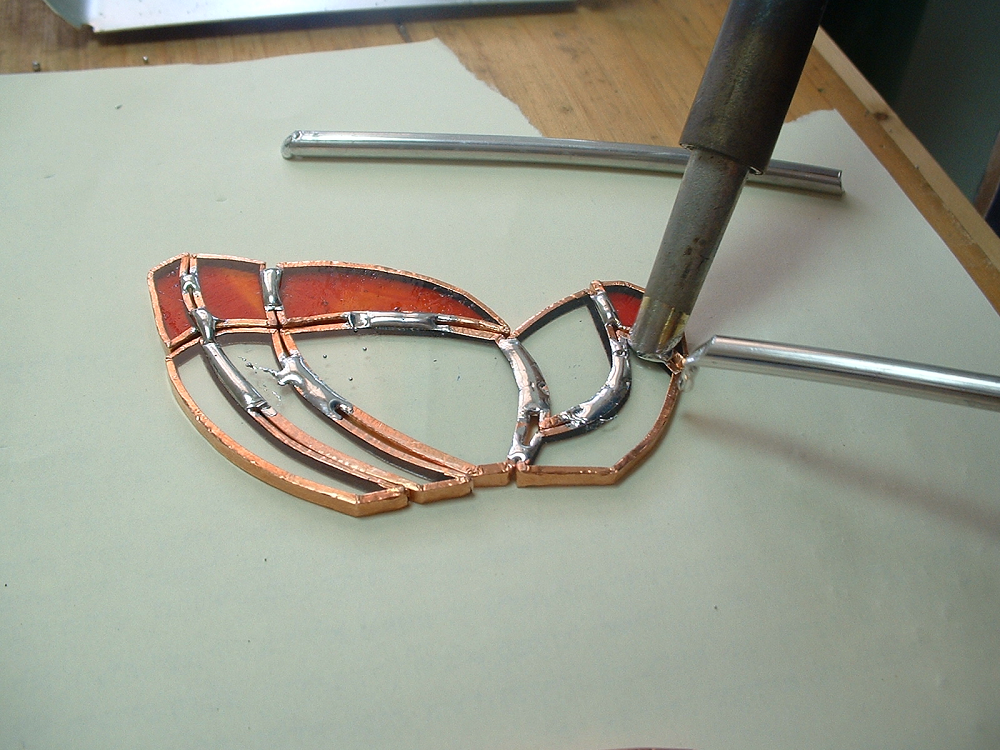

Indlela yokwenza i-foil usebenzisa ii-foil zobhedu

Ukuze uqale ukufoyila, qala ngokubophelela ifoyila kude nomphezulu weprojekthi. Oku kwenza unxibelelwano phakathi kweglasi enombala kunye neefoyila lube lomelele. Oku kungenxa yokuba ifoyila ayidibani nomphetho apho inokuthi ikhululeke khona. Xa ufoyila, jonga imigca enamanani yecandelo leprojekthi uze uqale apho ukuze ubone ukuba inamathele ngokufanelekileyo.

Kuphephe ukunyibilikisa kancinci njengoko iglu idla ngokunyibilika ize ingabambeki. Injongo yeglue kukugcina ifoyile injalo de kube yi-solder yokugqibela. Kwakhona, lungisa ububanzi befoyile yobhedu yangaphandle ukuze ubambe uzinzo olupheleleyo lwe-solder.

Ifoyile yobhedu kaRa

I-Ra copper foil ilungile xa kudluliswa ii-copper foils ngee-roller ezimbini. Oku kwenza i-copper foil ifumane ubukhulu obufanelekileyo kwiprojekthi. I-Ra copper igudile ngokwemvelo kwaye ngaloo ndlela iguquguquka ngakumbi, ingakumbi xa ijikeleza kwiindawo zokusebenza ezigobileyo. Okubalulekileyo kukuba, uburhabaxa bee-copper foils buyatshintsha ngenxa yezinto ezininzi ezifana noxinzelelo lwee-roller.

Iimpawu zefoyile yobhedu esemgangathweni

Iifoyile zekopolo zinceda ekudibaniseni iiglasi ngokusebenzisa i-solder. I-solder ayibambeki xa idibene neklasi yiyo loo nto kufuneka ifoyile yekopolo kwaye isebenza njengesiseko. I-Cevic Metal ibonelela ngeefoyile zekopolo ezisemgangathweni ophezulu kodwa ezinale mpawu.

·Ukuguquguquka: Ifoyile yobhedu esemgangathweni kufuneka isebenze kakuhle kwiindawo ezigobileyo. Oku kuthetha ukuba ifoyile kufuneka yolulwe ngomzamo omncinci ukuze ilingane kakuhle kwiglasi ngaphandle kokukrazuka. Iifoyile zobhedu zeeglasi ezingcolileyo nazo kufuneka zibe lula ukuzisebenzisa xa uzifaka.

·Ukuthamba: Ifoyile kufuneka ithambe ukuze inwebeke kakuhle kumphezulu weprojekthi. Iifoyile zobhedu ezithambileyo zihambelana kakuhle nemilo yeglasi xa kuthelekiswa neefoyile eziqinileyo. Okubalulekileyo kukuba, ayizizo zonke iifoyile ezithambileyo ezilungileyo. Singumthengisi osemthethweni wazo zonke iimfuno zeprojekthi yeglasi ingakumbi ezo zifuna iifoyile zobhedu ezithambileyo.

·Amandla: Ifoyile yobhedu efanelekileyo kufuneka iqine kwaye inamathele kakuhle ekufakweni kwayo. Iifoyile ezomeleleyo zisebenza kakuhle ngelixa zisusa naziphi na iingxaki.

Ukugcina i-copper foil ixesha elide

Iifoyile zekopolo zichaphazeleka lula kwiimeko zokusingqongileyo kwaye ukuzikhusela kubalulekile. Ukukhusela iifoyile zekopolo kunceda umntu ukuba aphephe iindleko ezinxulumene nokufumana enye endaweni yazo. Le yindlela onokuyandisa ngayo ubomi befoyile yekopolo.

·Gcina iifoyile zobhedu kwindawo epholileyo neyomileyo. Ingxowa engangeni moya yindlela efanelekileyo yokusebenzisa ixesha elide.

·Ukuzifaka kwiitini ezingangeni moya kuthintela ukufuma ekuchaphazeleni inkangeleko kunye nomgangatho wefoyile yobhedu.

I-Cevic Metal ibonelela ngeefoyile zobhedu ezingafaniyo nezinye ezifanelekileyo kwimisebenzi yobugcisa neyeemoto. Zonke iimveliso ezibonelelwayo zihlala ixesha elide xa kuthelekiswa neefoyile zobhedu eziqhelekileyo.

Ixesha lokuthumela: Julayi-05-2022